In today’s video well hear about a super material called fiberglass, and see how this material is used in marine and offshore jobs. It is known that fiberglass structural profiles are durable and strong – the ideal choice for these kinds of projects. So, let's get stuck in and find out why fiberglass is so cool.

Introduction to Fiberglass Structural Profiles

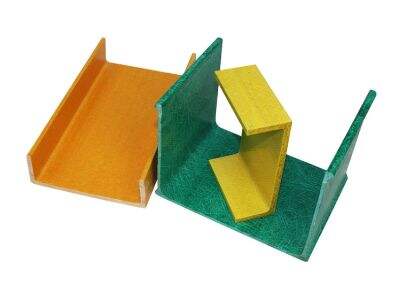

Fiberglass is any material that is composed of extremely fine fibers of glass. These fibers are created from glass, which is why it’s called fiberglass. Fiberglass structural shapes find wide applications in marine and offshore constructions due to their high strength and heavy duty requirements.

Advantages of Fiberglass for Marine and Offshore Applications

There are number of advantages of Fiberglass for marine and offshore applications. It is one of the greatest features is that fiberglass does not corrode or become damaged by water, therefore it is ideal for saltwater applications. It’s also hella light, so hauling and hanging it is a breeze. Fiberglass is also very moldable in terms of shape and size, so companies can work around custom forms for specific projects.

Use of fiber glass structural profiles in the marine sector

Fibreglass structural sections are applicable to all marine applications. They reside in boat hulls, docks, and even subaquatic structures like pipelines and oil rigs. Fiberglass profiles are also employed in the construction of the support beams and platforms for marine construction projects thus directly forming a rugged and dependable base for structures.

3.1Best practices from Case studies in Field Deployments (offshore)

Here’s how fiberglass structural profiles are successfully applied to an offshore project Offshore Wind Turbines As offshore structures continue to grow in popularity for a variety of reasons, fiberglass profiles are going to continue to be important to make these projects possible. These turbines must make use of tough materials that can stand up to the challenging environment of the open sea. Thanks to a housing from glass fiber profiles, engineers have developed a stable supporting frame for powerful winds and wild waves.

The construction of floating docks for marinas is another example, such as fibreglass profiles. These docks must face heavy boats and water, and be durable – as well as comfortable – enough to support any nuptial feelings. Fiberglass profiles are the ideal choice; offering engineers a material that is both durable and weather resistant.

What Lies Ahead for Fiberglass Structural Shapes in the Marine Industry

It seems that there is a bright future for the fiberglass structural profiles on the marine market. We should anticipate new, cutting-edge applications of fiberglass as technology continues to progress in the marine and offshore sector. Whether it’s underwater concrete structures or floating platforms, fiberglass will always be a major player in providing robust and long-lasting marine infrastructure.

Table of Contents

- Introduction to Fiberglass Structural Profiles

- Advantages of Fiberglass for Marine and Offshore Applications

- Use of fiber glass structural profiles in the marine sector

- 3.1Best practices from Case studies in Field Deployments (offshore)

- What Lies Ahead for Fiberglass Structural Shapes in the Marine Industry