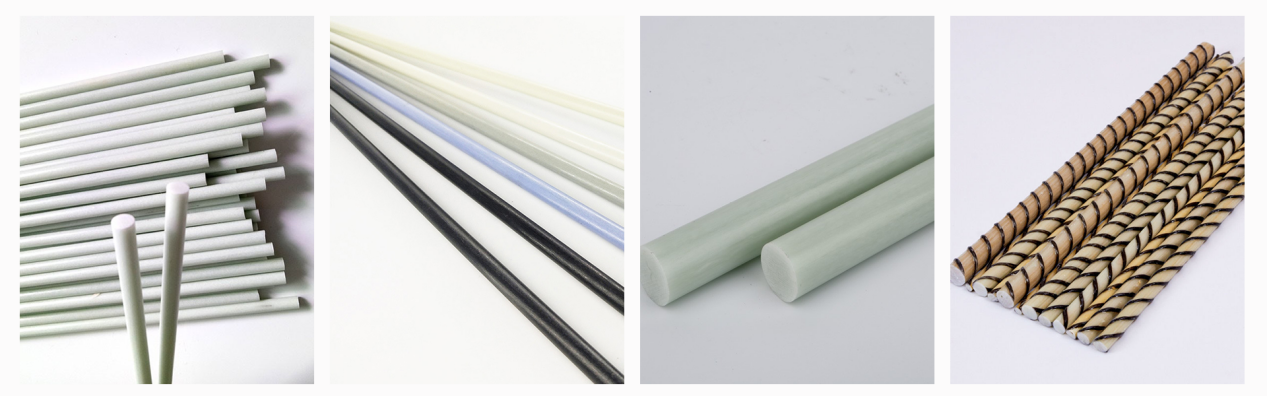

Hogyan erősíthető örvényekkel fibraglassz rúdokkal?

Bevezetés

A beton a modern építészet gerincének tekinthető, de a hagyományos acélgerinces megoldások korlátokkal rendelkeznek – rovarolódás, súlyosság és magas karbantartási költségek. Szivárványos rúdok (GFRP) újabb, jobb alternatívaként jelenik meg, amely könnyű, nem rovaroló és nagy erősséggel bír. Ez az útmutató bemutatja, miért és hogyan használható szivárványos rúdok a beton gerinces erősítésére, beleértve a technikákat, esettanulmányokat és szakértői tippjeket.

(Meta leírás: Tudj meg, hogyan szivárványos rúdok erősebb beton erősítés a választásnál acél—lépésről lépésre telepítés, előnyök és valós világi alkalmazások. Tervezőknek & mérnököknek alkalmas!)

Miért használni szivárványos rúdokat helyett acélt?

1. A Korróziós ellenállás

Az acél békasorok idővel oxidoszakad, különösen tengeri környezetekben vagy dejelezési sók tartalmazó területeken. Szivárványos rúdok , amelyek szivárványos szálból és polimeres rétegből készültek, oxidáció ellen kevésbé érzékenyek, így hosszabb élettartamot biztosítanak a szerkezeteknek.

Tanhely:

A Miami-i Közhasznos Hafen szivárványos erősítést használt a tuzsváb okozta kár megelőzése érdekében, ami által 40%-kal csökkentette a karbantartási költségeket.

2. könnyű súlyú és egyszerű kezelés

Szivárványos rúdok 75%-kal kisebb, mint a vas, ezért könnyebben szállíthatók és telepíthetők. Ez fontos a következőkben:

Magas épületek (csökkenti a strukturális terhelést)

Kotró munkák (nincs nehéz gépeszkedvesszük szükség)

3. Magas húzóerő

Míg a vas erősebb rugalmatlanságban, FRP rúdok nagyobb erő-súly arányt bírnak, amiért alkalmasak a következőkre:

Visszhangosan rezgésekhez predísztált területek ( rugalmas de tartós )

Hídképzések & autópályák ( törékenységt ellenálló stressz alatt )

4. Nem vezeték és nem mágneses

Ellentétben az acéllel, szivárványos rúdok ne zavarják az elektrikus vagy magneszes mezőket, ezért tökéletesek a következőkre:

Villamos erőművek

MR szoborok kórházakban

(Kulcsszavas alcím: "Vállalkalmas Vásznak és Acélvállalkalmas Vásznak – Melyik Jobb a Beton Fajtáihoz?")

Lépésről Lépésre: Hogy Fajtálíthatja a Betont Vállalkalmas Rácsokkal

Lépés 1: Tervezés & Tervezés

Konzultálj a mérnöki irányelvekkel (pl., az ACI 440.1R-15 a GFRP felszínes erősítéshez).

Számítsd ki a terhelési követelményeket a rúd átmérőjének és elhelyezésének meghatározásához.

2. lépés: Vágás és alakítás

Használj diamantfelvett lécet a vágáshoz szivárványos rúdok (a szokványos léccek szórógathatják a nyomokat).

Hajtsa ki a rúdokat ültőpárnával (ha szükséges), mivel nem lehetnek helyszínen hajtva, mint a vas.

Lépés 3: Beépítés

Hely szivárványos rúdok a formázóban (használjon plasztikos távolítókat az érintkezés elkerülése érdekében a talaj/törzsrel).

Rögzítse kötődrót vagy fibertegyenes kompatibilis klipekkel (kerülje a fémes kötést a galvanikus roham elkerülése érdekében).

Öntse ki egyenletesen a betont a kitérések elkerülése érdekében.

Lépés 4: Meghajtás és Ellenőrzés

Hagyja, hogy a beton meghajtsa 28 napig (a szörfűrész anyag nem befolyásolja a meghajtó időt).

Ellenőrizze a helyes igazítást a szerkezet véglegesítése előtt.

(Pro tipp: "Használj époxy-zúzott szivárványos rúdok kémiai környezetekben extra védelemért!")

Valóságos Alkalmazások

1. Infrastrukturaprojektek

Kanada 407-es autópálya GFRP áramvonalakat használt a só okozta romlás elkerülése érdekében.

Japán repülővezetékes vonalainak tünnelei sziklaszivattyúra támaszkodnak a szélsőségek ellenállásához.

2. Lakhelyi és kereskedelmi használat

Padlók és alapok part menti otthogorombákban.

Balkonok és úszómedencék (nincs rézspöttyök).

3. Ernevelhető energia

Szélturbínák alapjai (jobban ellenáll az időjárásnak, mint a vas).

Gyakori hibák, amelyeket elkerülnünk kell

❌ Fém kötél használata (galvanikus rovásokat okoz).

❌ Helytelen távolságtervezés (gyenge pontokhoz vezet).

❌ UV-védelem figyelmen kívül hagyása (a feltettként maradó rúdok idővel romlik).

A szilíciumszövett erősített beton jövője

A nanotechnológiai és hibrid kompozit fejlesztésekkel együtt, szivárványos rúdok megy:

Erősebbek (új rézsmódotások).

Olcsobbak (a tömegtermelés csökkenti a költségeket).

Több szempontból alkalmazhatóbb (3D-nal nyomtatott szilícaglászeres szerkezetek).

Összegzés

Szivárványos rúdok forradalmas változást hoznak a beton erősítésében, hosszabb időre tartó, könnyebb és rohamellenes megoldást kínálva. Függőhídaknál, otthonoknál vagy ipari projekteknél is, a GFRP-re való áttéréssel csökkenthetők a költségek és növelhető az ereklye.

Hívás a cselekvésre:

"Szeretnél megpróbálni szivárványos rúdok a következő projektjeidben? [Lépjen kapcsolatba velünk] ingyenes mintákért vagy töltse le telepítési útmutatót!