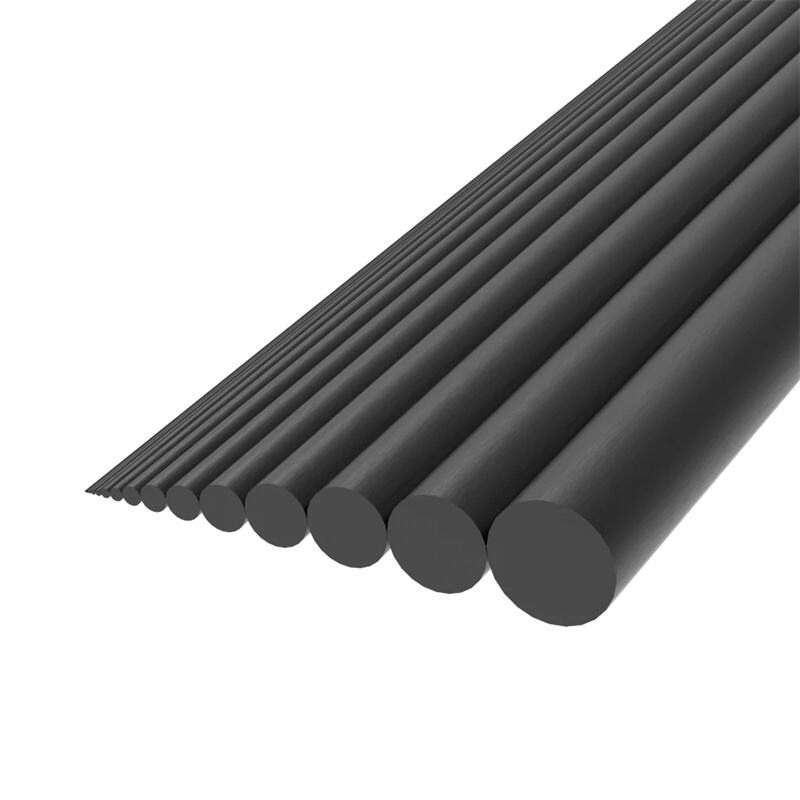

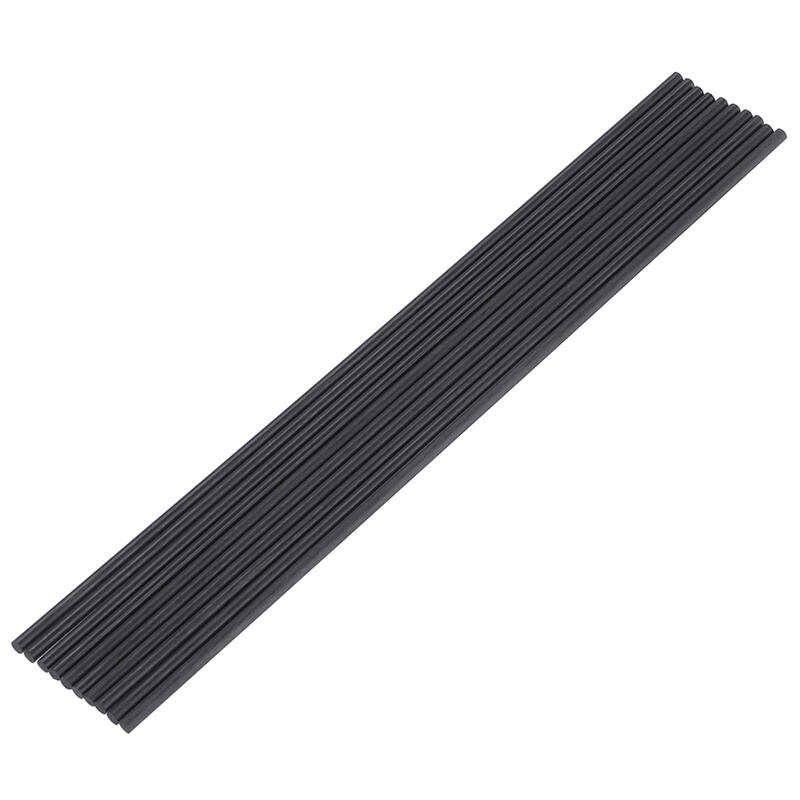

Carbon Fiber Rods for Sale - Solid & Hollow Rods in Multiple Sizes

- Overview

- Recommended Products

Carbon fiber rod:A carbon fiber rod is a high-performance structural component made from aligned carbon fibers bonded with a polymer resin (typically epoxy). The fibers provide exceptional strength and stiffness along the rod's length.

PROPERTY

• High Strength-to-Weight Ratio: Stronger than steel at a fraction of the weight (~1/4 to 1/5).

• High Stiffness (Modulus): Excellent resistance to bending and deflection.

• Low Thermal Expansion: Dimensionally stable across temperature ranges.

• Corrosion & Fatigue Resistant: Does not rust and withstands repeated stress cycles well.

• Good Vibration Damping: Absorbs and dissipates energy effectively.

• Electrically Conductive: A consideration for electrical applications (can be pro or con).

• X-Ray Transparent: Useful in medical and aerospace imaging.

Specifications

Carbon Fiber Rod Types & Characteristics Comparison Table

| Type | Primary Process | Key Characteristics | Pros | Cons | Typical Applications |

| Solid Round Rod | Pultrusion | Solid cylinder, smooth surface. | Highest bending stiffness, cost-effective, readily available, easy to mount. | Lower weight efficiency than tubing, can be heavy for its diameter. | Light structural struts, push/pull rods, shafts, DIY projects, tool handles. |

| Hollow Round Tube | Pultrusion / Roll Wrap | Hollow cylinder, most common form. | Best stiffness-to-weight ratio, large diameter for high inertia, versatile. | Ends require reinforcement to prevent crushing, connection can be more complex. | UAV arms, robotic frames, sports equipment (e.g., fishing rods), structural beams. |

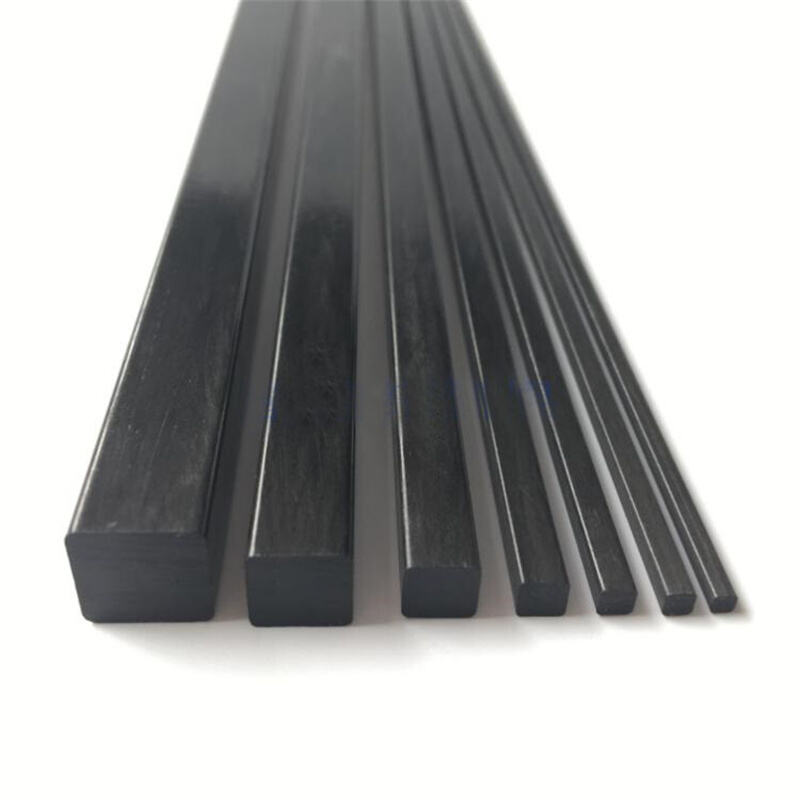

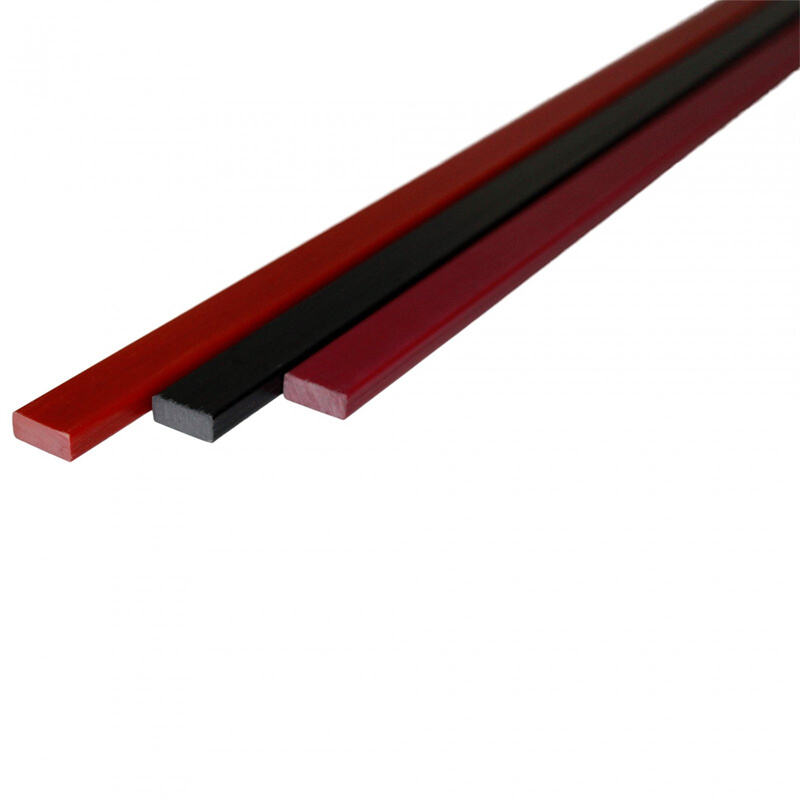

| Square / Rectangular Tube | Pultrusion / Molding | Square or rectangular cross-section. | Easy to fixture and align to flat surfaces, good torsional resistance. | Stress concentration at corners, slightly heavier than round tube (for same perimeter). | Frame structures, rails, lightweight trusses, automation frames. |

| High Modulus Rod/Tube | Roll Wrap / Filament Wind | Made from ultra-high-modulus carbon fiber. | Exceptional rigidity, minimal deflection, extremely lightweight. | Very expensive, can be more brittle with lower impact resistance. | Aerospace components, high-end racing drones, precision instruments, top-tier fishing rods. |

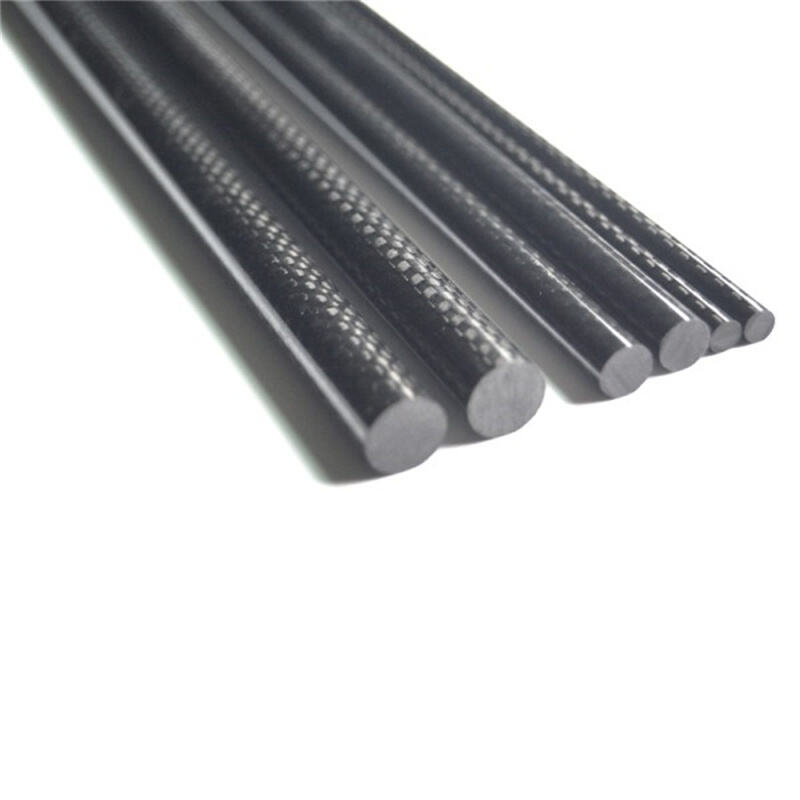

| Surface Finish | - | Glossy vs. Matte vs. 3K Twill Weave. | Glossy/Matte (Pultruded): Low cost, hard surface.Twill Weave (Roll Wrapped): Aesthetic, slightly better tear resistance. | Weave surface is typically more expensive; texture may affect adhesive bonding. | Consumer/Aesthetic Parts: Choose woven.Industrial/Structural: Choose cost-effective glossy/matte. |

Applications

Aerospace & Drones: UAV arms, structural supports, antenna rods.

Robotics & Automation: Lightweight arms, frames, and linkages for high speed and precision.

High-End Sporting Goods: Fishing rods, kite spars, tent poles, arrow shafts, crossbow bolts, drone racing frames.

Industrial & DIY: Pushrods (RC planes, machinery), trusses, calibration tools, prototypes.

Medical: Components for imaging equipment, prosthetics, surgical tools.

Automotive: Lightweight components for racing and high-performance vehicles.

MANUFACTURING PROCESSES

Pultrusion: Most common for straight rods. Cost-effective, yields a smooth, glossy finish.

Roll Wrapping: Uses prepreg fibers for higher performance and a true woven appearance.

Filament Winding: Fibers are wound at specific angles, ideal for hollow tubes and torsional control.

Compression Molding: For complex or non-uniform shapes.

PACKING AND STORAGE

1.Palletization (for large orders):

Multiple cartons are securely stacked and strapped to a standard export wooden pallet.

The entire pallet load is then wrapped tightly with stretch film and/or covered with a waterproof plastic sheet for unitization and weather protection.

2.Tertiary Protection (Master Carton):

The tube(s) are then placed inside a heavy-duty, corrugated export-grade master carton.

All void spaces within the carton are filled with PE foam peanuts, air cushions, or custom-cut foam inserts to eliminate any movement during transit.

The carton is clearly labeled with handling icons ("Fragile," "Do Not Bend," "Keep Dry," "This Side Up") and product information (P/N, Qty, Length, etc.).