Kaj je bolje steklena ojačitev ali TMT palica?

Osnovni steber sodobne gradnje, od visečih nebodirkov do skromnih parkirišč, je armiran beton. Več kot sto let je neomejeni kralj tega področja jeklo, najpogosteje v obliki termomehansko obdelanih (TMT) palic. A iz laboratorijev materialov znanosti se je pojavil zelo močan izzival: Steklovinska armaturna štanga .

Osnovni steber sodobne gradnje, od visečih nebodirkov do skromnih parkirišč, je armiran beton. Več kot sto let je neomejeni kralj tega področja jeklo, najpogosteje v obliki termomehansko obdelanih (TMT) palic. A iz laboratorijev materialov znanosti se je pojavil zelo močan izzival: Steklovinska armaturna štanga .

Vprašanje, ki se odmeva po gradbiščih, inženirskih podjetjih in projektantskih birojih, je preprosto, a ključno: Katero je bolje, steklovinska armaturna štanga ali TMT palica?

Odgovor, kot v večini kompleksnih inženirskih področij, ni preprost. Odvisen je od množice dejavnikov, vključno z okoljem projekta, proračunom, konstrukcijskimi zahtevami in dolgoročnimi cilji vzdrževanja. Ta članek podrobno raziskuje to sodobno gradbno dilemo in ponuja celovito primerjavo za podporo vašemu odločanju.

Razumevanje tekmencev: Uvodnik

Kaj je TMT palica?

TMT palica (termomehansko obdelovana palica) je visokotrdna armaturna jeklena palica z mehkim, duktilnim notranjim jedrom in trdim, močnim zunanjo površino. To edinstveno strukturo dosežemo s sofisticiranega proizvodnega procesa, ki vključuje hitro vodno zakaljevanje po valjanju na vročo. Rezultat je palica, znana po izjemni upogljivosti, visoki mejni tečnosti in odličnem oprijemu s betonom. Je tradicionalni, preverjeni in najpogosteje uporabljeni armaturni material na svetu.

Kaj je stekleno vlakno (GFRP)?

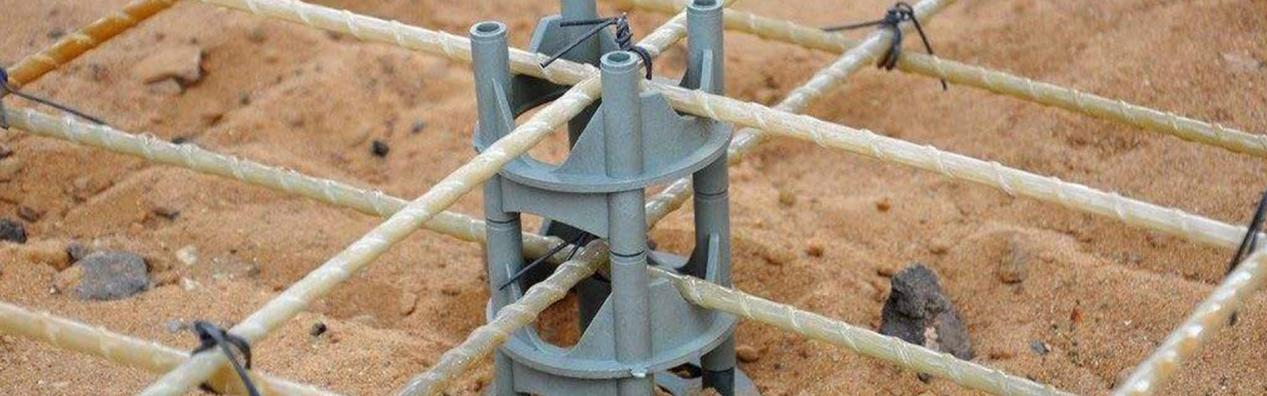

Steklovinska armaturna štanga , bolj natančno imenovano armaturna palica iz steklenih vlaken v polimeru (GFRP), je kompozitni material, sestavljen iz neprekinjenih steklenih vlaken, vdelanih v matrico polimerne smole (najpogosteje vinilne estrske). Vlakna zagotavljajo ogromno vlečno trdnost, medtem ko smola ščiti vlakna in prenaša napetost med njimi. Je nekorozivna, neprevodna in lahka alternativa jeklu.

Primerjava po krogih: Ključni dejavniki

Da bi določili zmagovalec, moramo te dve materiali med seboj primerjati v ključnih področjih, ki so najpomembnejša pri gradnji.

Prvi krog: odpornost proti koroziji – dejavnik, ki spreminja pravila igre

To je najpomembnejša prednost steklovinska armaturna štanga in glavni razlog za njegovo razvoj.

TMT palica: jeklo je zaradi svoje narave dovzetno za korozijo. Sol iz razmerzilnih sredstev ali morske vode skupaj z karbonatacijo zaradi CO2 v zraku lahko prodre v beton in povzroči rjavenje. Rjava zasede več prostora kot jeklo, kar povzroča razpokanje in lupljenje betona, kar vodi v katastrofalno strukturno odpoved. Epoksi premazi (armaturne palice) lahko pomagajo, vendar so ranljivi za poškodbe med rokovanjem in litjem.

Fiberglass Rebar: GFRP je popolnoma odporen proti napadu kloridnih ionov in se ne rja. Prav tako ni vpliven široko spektrum kislin, alkalijev in drugih kemikalij, ki se pogosto pojavljajo v industrijskih okoljih. Zaradi tega postaja nedvoumni prvak med strukturami, ki so izpostavljene ekstremnim okoljem.

Zmagovalec: Steklena ojačitev. Za morske konstrukcije, mostove, čistilne naprave, kemične obrate in parkirišča je GFRP pogosto edina izbira za dolgotrajno vzdržljivost.

Krog 2: Vlečna trdnost – Surova moč

TMT palica: TMT palice imajo visoko vlečno trdnost, ki se običajno giblje med 415 MPa in 550 MPa za običajne razrede (Fe 415, Fe 500, Fe 550). Njihova trdnost je dobro razumljiva in napovedljiva.

Steklena ojačitev: Gfrp armatura ima vlečno trdnost, ki je znatno višja od jekla – pogosto 2 do 3 krat večja za enak premer. GFRP palica s premerom 5 (16 mm) lahko doseže vlečno trdnost nad 1000 MPa.

Zmagovalec: Steklena ojačitev (na papirju). Vendar moramo narediti pomembno razliko. Jeklo je elastično-plastični material. Pri ekstremnih obremenitvah se deformira, pri čemer so vidni znaki opozorila (upogibanje, razpoke) pred končno odpovedjo. GFRP je linearno-elastičen; ne deformira se. Raztegne se in nato nenadno in katastrofalno odpove brez opozorila. Pomanjkanje duktilnosti je pomembno oblikovalsko vprašanje.

Tretji krog: Teža in rokovanje – Logistika

TMT palica: Jeklo je gosto in težko. 12-metrski kos palice #6 (20 mm) tehta približno 30 kg, za rokovanje pa so potrebna mehanska orodja (žerjavi, vezniki za ojačitev), pa tudi več delavcev, kar povečuje čas in stroške dela.

Steklovinska armaturna štanga : GFRP je približno 75 % do 80 % lažji od jekla. Enaka palica #6 bi lahko tehtala le 7 kg. To omogoča lažje, hitrejše in varnejše rokovanje z rokami. Zmanjša potrebo po težki opremi na gradbišču, zmanjša stroške prevoza in zmanjša tveganje za poškodbe delavcev.

Zmagovalka: Steklena ojačitev. Logistične prednosti so jasne, kar vodi do možnih prihrankov časa in dela.

Krog 4: Toplotno razširjanje in toplotna prevodnost

TMT palica: Hitrost, s katero se jeklo razširja ob segrevanju, je precej primerljiva z betonom, okoli 10–12 x 10⁻⁶/°C. To pomeni, da se ob spreminjanju temperature oba materiala razširjata in krčita skoraj enako hitro, kar preprečuje notranje napetosti. Jeklo je tudi odličen električni in toplotni prevodnik.

Steklena ojačitev: GFRP ima vzdolžno nižji in drugačen koeficient toplotnega razširjanja (približno 6–10 x 10⁻⁶/°C), prečno pa veliko višji. Ta neujemanje lahko potencira težave v okoljih z ekstremnimi temperaturnimi nihaji. Pomembno je, da je GFRP električni in toplotni izolator.

Zmagovalec: Neodločeno. Nezdružljivost toplotnega raztezanja je slabost pri GFRP, ki zahteva previdno načrtovanje. Kljub temu so njegove izolacijske lastnosti velika prednost za določene aplikacije, kot so MRI objekti, raziskovalne laboratorije ali konstrukcije, kjer je električna izolacija ključna, kar pomeni situativno prednost.

Krog 5: Stroški – končna cena

TMT palica: Jeklo je surovina s stabilno globalno dobavno verigo. Njegova začetna stroška materiala sta precej nižja v primerjavi z GFRP-jem. Za večino standardnih projektov je TMT v času nakupa bolj ekonomična izbira.

Steklena ojačitev: Začetna nakupna cena Gfrp armatura je višja, pogosto 2 do 4 krat večja kot pri enakovredni TMT palici glede na dolžino. Vendar je to le prvi del enačbe stroškov. Treba je upoštevati stroške v življenjski dobi (LCC).

Zmagovalec: Odvisno. Za garažo na dvorišču je TMT najbolj ekonomična izbira. Za večji most v obalnem območju pa astronomsko visoki stroški prihodnjega vzdrževanja, popravil in zgodnjega ponovnega gradnje zaradi korozije jekla naredijo iz steklenih vlaken narejeno armaturo bolj ekonomično izbiro v 100-letnem življenjskem ciklusu objekta. Višji začetni vlog se povrne z izogibanjem prihodnjim stroškom popravil.

Sodna odločitev: uporaba je vse.

Ni enega samega »boljšega« materiala. Vse je odvisno od konkretnih zahtev projekta.

Izberite TMT palico (preverjeno delovno konja) za:

Standardno gradnjo objektov: Stanovanjske hiše, poslovne zgradbe in industrijske konstrukcije v neagresivnem okolju.

Projekti z omejenim proračunom: Tam, kjer je začetna cena glavni dejavnik.

Konstrukcije, ki zahtevajo duktilnost: V seizmično aktivnih območjih, kjer je sposobnost jekla, da se deformira in absorbira energijo, ključna za odpornost proti potresom.

Zloženi dizajni: Projekti, ki zahtevajo veliko upogibanja in ponovnega oblikovanja armaturnih palic na gradbišču (čeprav je mogoče naročiti že upognjene GFRP palice iz tovarn).

Izberite stekleno vlakno za armaturo (The Modern Specialist) za:

Morske in vodne konstrukcije: Mole, obalne zidove, pristajališča in ladje sidrišča.

Prometna infrastruktura: Mostne konstrukcije, ograje in vozišča, kjer se uporabljajo soli za odmrzovanje.

Čistilne naprave za odpadno vodo: Rezervoarji, usedalniki in cevovodi, ki so izpostavljeni visoko korozivnim kemikalijam.

Specializirane uporabe: MRI sobe, znanstveni laboratoriji, elektroenergetske razdelilne postaje in območja, kjer je potrebna elektromagnetna nevtralnost (npr. vojaške ali podatkovne objekte).

Ozelenjevalne in arhitekturne aplikacije: Tam, kjer je za vidni beton potreben netrujen, čist izdelek.

Prihodnost ojačevanja

Gradbeni sektor se razvija v smer k pametnejšim, bolj trpežnim in bolj trajnim materialom. Kljub temu bo TMT palica ostala vodilna sila v klasični gradnji še več desetletij zaradi svoje cene in duktilnosti, vendar se trg GFRP-ja hitro razširja. steklovinska armaturna štanga se hitro razširja.

Raziskave potekajo za premoč GFRP-jevih omejitev, še posebej krhkosti in vedenja pri požaru. Razvoj kombiniranih palic, ki združujejo jeklo in FRP, bo morda enkrat ponudil »najboljše izmed obeh svetov«.

Zaključek: Vprašanje konteksta

Torej, katera izbira je boljša: steklena armaturna mreža ali TMT palica?

Za trpežnost v korozivnih okoljih in dolgoročne prihranke pri velikih, kritičnih infrastrukturah, Steklovinska armaturna štanga je boljša izbira.

Pri vsestranski gradnji, odpornosti proti potresom in najnižji začetni ceni ostaja TMT palica nepremagljiv prvak.

Resnični znak previdnega inženirja, arhitekta ali vodje projekta ni v tem, da bi enega izbrali namesto drugega univerzalno, temveč v razumevanju njihovih edinstvenih lastnosti in izbiri pravega orodja za pravo delo. Pri trajujoči gradbeni razpravi bo vedno odločilna okoliščina.