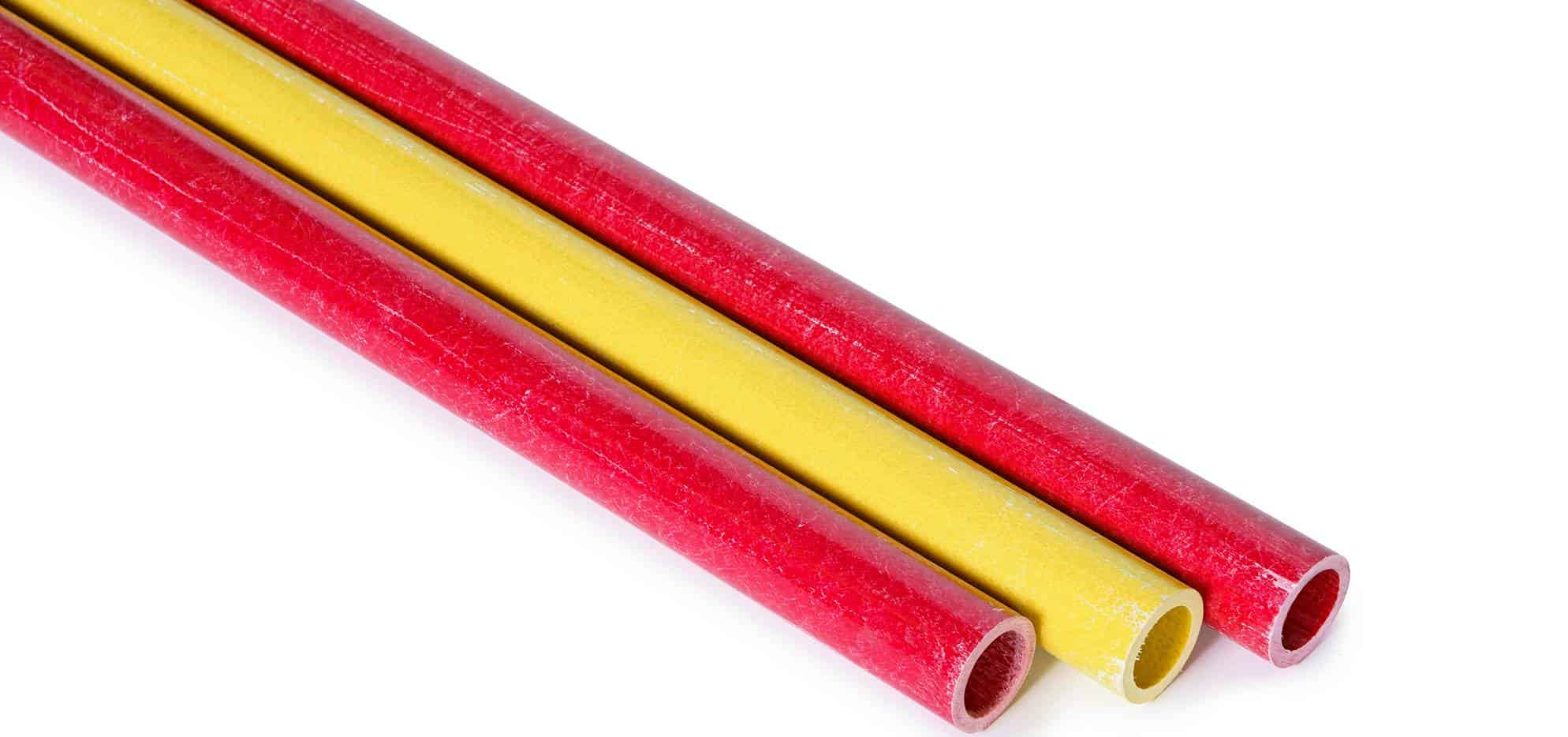

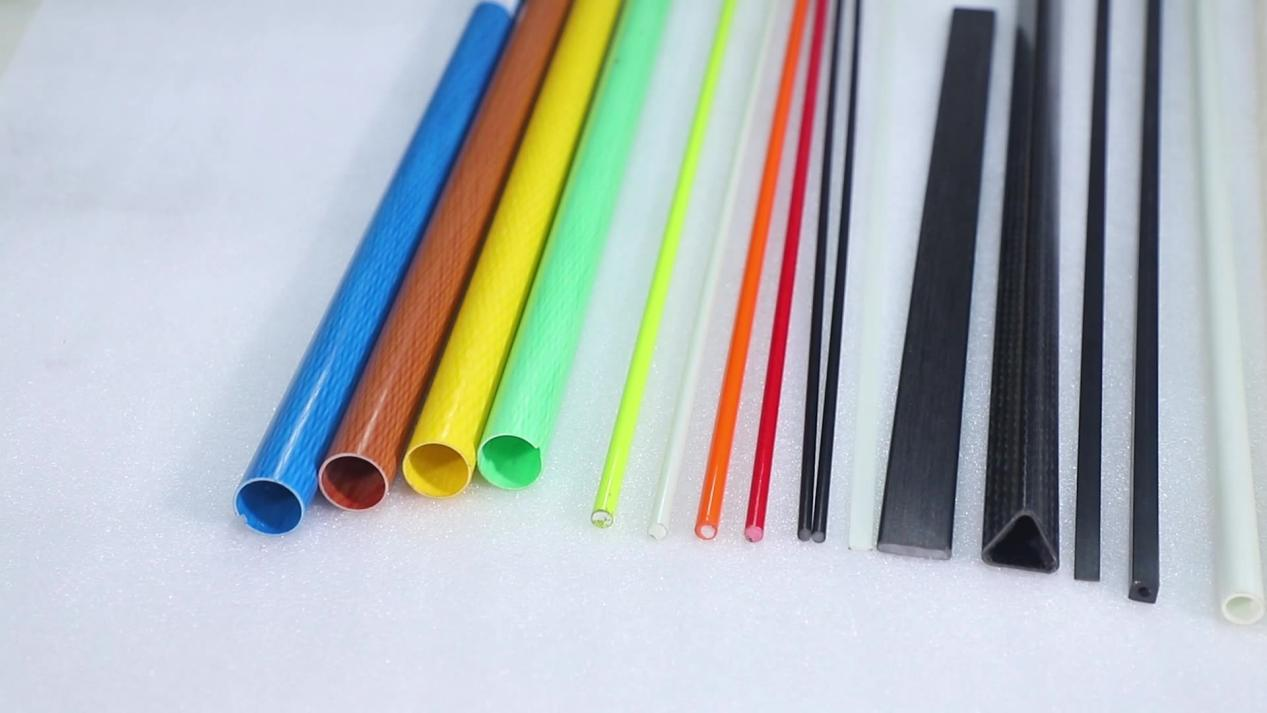

Top 10 Manufacturers of Fiberglass Tubes and Tubing in 2025

The global fiberglass tube market is booming, projected to reach new heights in the coming years. Driven by demand from construction, aerospace, marine, and electrical industries, the need for strong, lightweight, and corrosion-resistant tubing has never been greater. However, with so many companies claiming to be the best, how do you, as an engineer, procurement manager, or DIY enthusiast, choose the right supplier?

Selecting the wrong manufacturer can lead to project delays, cost overruns, and even safety hazards. The right partner, on the other hand, delivers not just a product, but reliability, technical expertise, and value.

To simplify your sourcing process, we've compiled a comprehensive list of the top 10 fiberglass tube manufacturers in 2025. This list is curated based on factors like global reputation, product quality, technical innovation, range of offerings, and customer service.

Why the Choice of Manufacturer Matters

Before we dive into the list, let's understand why this decision is critical. Fiberglass tubes are not a generic commodity. Their performance is determined by:

Resin Formulation: Epoxy, polyester, and vinyl ester resins offer different properties in terms of chemical resistance and temperature tolerance.

Fiber Orientation: The alignment of the glass fibers dictates strength and flexibility.

Manufacturing Process: Pultrusion, filament winding, and centrifugal casting produce tubes with distinct characteristics.

Quality Control: Consistent diameter, wall thickness, and surface finish are signs of a superior manufacturer.

A top-tier manufacturer excels in all these areas, providing certified, reliable products backed by engineering support.

The Top 10 Fiberglass Tube Manufacturers in 2025

1. AMT Composites (Advanced Pultrusion Technology)

AMT Composites is often the first name that comes to mind for high-quality pultruded fiberglass tubing. They are renowned for their exceptional consistency and tight tolerances. With a global distribution network, they serve a wide array of industries, from medical equipment to industrial automation. Their strength lies in their ability to produce custom profiles and sizes with remarkable precision, making them a go-to for OEMs with specialized needs.

2. Strongwell (A Legacy of Strength)

As a dominant player in the North American market, Strongwell has built a reputation over decades for producing incredibly durable structural FRP products. Their DURAGRID® and DURADEK® platforms are famous, but their pultruded tubing is equally robust. They are the preferred choice for heavy-duty applications in construction, water treatment plants, and infrastructure projects where structural integrity is non-negotiable.

3. Creative Pultrusions, Inc.

Another giant in the pultrusion industry, Creative Pultrusions offers one of the most extensive catalogs of standard fiberglass tube shapes and sizes. They are a fantastic resource for standard and custom solutions, with a strong focus on the architectural and construction sectors. If you need a reliable, well-understood profile for a handrail, structural frame, or electrical conduit, they are a top contender.

4. Zoltek (A Carbon & Glass Fiber Powerhouse)

While Zoltek (a Toray company) is globally famous for its carbon fiber, their expertise in composites extends to high-performance fiberglass materials and tubing. They are a key supplier for the wind energy, automotive, and aerospace industries. For projects that demand a high strength-to-weight ratio and are pushing the boundaries of performance, Zoltek's advanced material solutions are worth investigating.

5. Fibrex Group

Fibrex Group has carved out a strong niche by focusing on specific, demanding applications. They are particularly noted for their fiberglass tubing used in electrical insulation, lightning protection systems, and the renewable energy sector. Their products often come with specific certifications and testing reports, providing an extra layer of confidence for critical applications.

6. Enduro Composites

A specialist in custom fiberglass and carbon fiber tubing, Enduro Composites excels at working directly with clients to develop tailored solutions. They are not just a manufacturer but a problem-solving partner. If your project involves unique environmental challenges, specific mechanical properties, or complex geometries, Enduro's engineering team has the capability to deliver.

7. Jamestown Distributors (The Distributor & Fabricator)

Unlike others on this list, Jamestown Distributors is primarily a distributor, but they are included for their immense value to a specific audience: boat builders, marine enthusiasts, and DIYers. They source quality tubing from reputable manufacturers and provide it in accessible quantities with excellent customer service and expert advice. For one-off projects or marine applications, they are an invaluable resource.

8. Bedford Reinforced Plastics

Bedford focuses on custom pultrusion and is known for its hands-on customer service and flexibility. They cater to both large and small orders, making them an excellent partner for startups and businesses with evolving needs. Their ability to handle smaller custom runs without sacrificing quality is a significant advantage for companies prototyping or in low-volume production.

9. TUF-BAR (The Concrete Reinforcement Specialist)

TUF-BAR has a clear and powerful focus: producing fiberglass rebar and tubing for concrete reinforcement. In an era where corrosion of steel rebar is a multi-billion dollar problem, TUF-BAR provides a compelling alternative. If your project involves concrete structures in corrosive environments (marinas, bridges, parking garages), they are a dedicated expert you should consult.

10. MFG Composites

MFG Composites offers a broad range of fiberglass products, including a wide selection of tubing. They are known for their competitive pricing and efficient service, making them a strong option for standard applications where budget is a primary concern without a complete compromise on quality. They serve various markets, including industrial, transportation, and sporting goods.

How to Make Your Final Choice: A Buyer's Checklist

Now that you have the list, how do you narrow it down? Use this checklist:

Define Your Application: Is it structural, electrical, or cosmetic? What are the load, environmental, and temperature requirements?

Check for Certifications: Look for ISO 9001, ASTM test reports, or industry-specific certifications (e.g., UL, MIL-SPEC).

Evaluate Customization Capabilities: Do you need a custom size, color, or resin formulation? Not all manufacturers offer this.

Assess Technical Support: Can you speak to an engineer? A supplier that offers technical consultation is often more valuable than a slightly cheaper one that does not.

Consider Logistics & Scale: Does the manufacturer have the capacity for your order volume and can they ship to your location efficiently?

Request Samples: Any reputable manufacturer will provide samples for evaluation. Test them!

The Future is Fiberglass

The manufacturers listed above are at the forefront of the composite materials revolution. As industries continue to seek lightweight, durable, and sustainable alternatives to traditional materials like steel and aluminum, the innovation from these companies will only accelerate.

Choosing from this list of top 10 fiberglass tube manufacturers in 2025 is your first step toward a successful, durable, and cost-effective project. Invest time in researching these leaders, and you will find a partner that can provide not just a product, but a competitive advantage.

Ready to start a conversation? We recommend reaching out to 2-3 companies from this list that best match your application to request quotes, technical data sheets, and samples.