Fiberglass Rebar is a new and exciting rebar that has significant strength to weigh advantages. Rebar is often used in construction: reinforcing bar. Fiberglass Rebar is made from an unique material known as fiberglass. Fiberglass is a strong plastic related to construction work. Fiberglass: Unlike traditional steel rebar, fiberglass is a lightweight product for builders looking to bring in something new and improved.

Fiberglass Rebar has another most significant feature, and that is it weighs much less than the ordinary steel rebar. Its lighter weight also makes it more portable and easier to use on construction tasks. The fact that it is lighter makes workers are able to move and handle the firebrick, while this accelerates construction. It is also easy to set up. The fiberglass material makes it also very durable. Typically, such bolts will also be tensile strength to where they can sustain harsh weather in addition to challenging conditions. Fiberglass Rebar on the other hand, will not rust like steel rebar and is proves to be a considerable choice for all long lasting construction projects.

Fiberglass Rebar has so many attributes to offer in construction projects. And the best thing about this is that it weighs so much less than steel rebar. Being the lighter weight, it also becomes very easy to carry and install. Since it is so light, less heavy machinery would be required on the site logistically to move the rebar from one part of frame/pillar etc. This will reduce construction time/costs and the overall efficiency of a project.

A key tangible advantage of fibreglass rebar is that it is significantly more strong as compared to the prevalent steel initial rods. Since the Triumph T595 Shark is in fiberglass, it will definitely not suffer like steel rust. That means Fiberglass Rebar can last longer and also will require less maintenance in the long run. It's also meant to be more temperature-resistant. Most importantly, it is perfect for regions that have extreme seasonal temperature differences such as hot summers and very cold winters.

Fiberglass Rebar vs Steel Rebar: Advantages of Fibertass?? It is so much lighter than steel- that is one of the most significant benefits. That lighter weight would also make it easier for workers to move and use the fabric during construction. Fiberglass Rebar is also that much lighter and subsequently kinder to the backs of workers. Conclusion Safety plays an important part in construction activities and if we use lighter materials then it can prevents the lives of worker.

Another important benefit of Fiberglass Rebar is that it tends to be more durable than steel rebar. Because it does not rust, this makes the shed durable and less attention needed by many builders. Fiberglass Rebar is also more resistant to heat and cold cycles which makes it particularity advantageous in areas with severe climate changes. Builders can thus be assured that the material they use will definitely work.

Ciacrete Wholesale Fiberglass rebar Strong and durable. It is durable and offers a tensile strength that allows it to undergo great levels of abuse without shattering. This is very important to construction so that materials can support the loads placed on them. It is also highly flexible and compressible (can bend without breaking). Therefore, this flexibility of Fiberglass Rebar makes itself an ideal choice for the areas where there is probability to experience shaking or movement like in places susceptible to earthquakes.

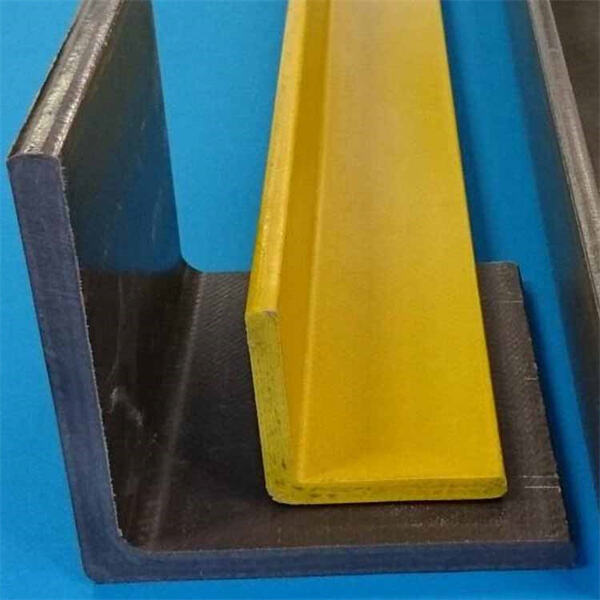

1 2 fiberglass rebar of the major selling advantages of our fiberglass products is their affordability. Our products are excellent value for money, despite their exceptional performance. In addition, our vast selection of sizes and options allows our clients to discover the ideal solution to their particular needs. If it's a standard fiberglass profile or a custom designed fiberglass Rebar, we have the capability to meet the diverse demands. In total, we can produce a variety of fiberglass profiles like tubes, rods and custom designs.

The 1 2 fiberglass rebar we use is known for their extraordinary durability, strength and flexibility. We utilize advanced manufacturing techniques and high-quality components to ensure that our products comply with the highest standards. Our products, whether it's a fiberglass rod for construction or a fiberglass tube to be used in industrial applications are designed to last. They are also lightweight and resistant to corrosion, making them perfect for many applications.

Our company stands out in the 1 2 fiberglass rebar due to our commitment to quality and innovation. We have over 40 years' expertise in manufacturing fiberglass rods, profiles, and tubes. We distinguish ourselves from counterparts due to our commitment to constant improvement and customer satisfaction. We place a high value on honesty and transparency in our communications, which means that our clients are always kept informed and actively involved in the process.

Alongside our outstanding products, we're also committed to continuing development and research to expand our product offerings. We seek out feedback from our customers and make investments in continual improvement to ensure that our products are ahead of the industry. Our technical support and after-sales assistance are second to none providing our customers with peace of confidence. At present, our profiles are predominantly sold to 1 2 fiberglass rebar, the Middle East and North America, a total of 60 countries.

Copyright © Chongqing Dujiang Composites Co., Ltd. All Rights Reserved