Fiberglass Rectangular Tubes: Key Benefits and Industrial Applications

Introduction

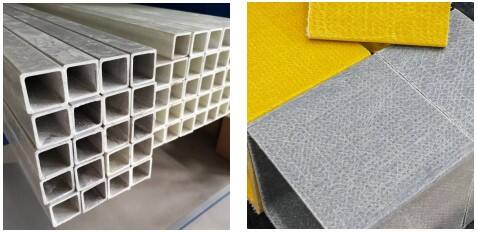

Fiberglass reinforced plastic (FRP) rectangular tubes are increasingly becoming a preferred choice in various industries due to their durability, lightweight nature, and resistance to harsh environmental conditions. Unlike traditional materials like steel or aluminum, fiberglass rectangular tubes offer superior corrosion resistance, electrical insulation, and design flexibility.

This article explores the key benefits of fiberglass rectangular tubes and their diverse industrial applications, helping engineers, architects, and procurement specialists make informed decisions for their projects.

1. What Are Fiberglass Rectangular Tubes?

Fiberglass rectangular tubes are structural profiles made from fiberglass-reinforced polymer (FRP). They consist of glass fibers embedded in a resin matrix, typically polyester, vinyl ester, or epoxy. The rectangular shape provides excellent strength-to-weight ratios, making them ideal for load-bearing applications where metal alternatives may fail due to corrosion or excessive weight.

Key Features:

✔ Lightweight (up to 75% lighter than steel)

✔ High strength-to-weight ratio

✔ Corrosion-resistant (ideal for chemical & marine environments)

✔ Non-conductive (safe for electrical applications)

✔ UV and weather-resistant

✔ Low thermal conductivity

2. Key Benefits of Fiberglass Rectangular Tubes

2.1 Corrosion Resistance

Unlike metal tubes, fiberglass rectangular tubes do not rust or corrode, even in:

Chemical plants (acid & alkali exposure)

Marine environments (saltwater resistance)

Wastewater treatment facilities (resistant to hydrogen sulfide)

This makes them a long-term cost-saving solution, eliminating the need for frequent replacements.

2.2 Lightweight Yet Strong

Fiberglass tubes are significantly lighter than steel or aluminum, reducing:

Transportation costs

Installation labor

Structural load in buildings and bridges

Despite their lightweight nature, they offer high tensile strength, comparable to some metals.

2.3 Electrical Insulation Properties

FRP rectangular tubes are non-conductive, making them ideal for:

Electrical enclosures

Utility poles & cable trays

Telecommunication structures

This eliminates risks of short circuits and improves workplace safety.

2.4 Design Flexibility & Customization

Manufacturers can produce fiberglass rectangular tubes in:

Various sizes & thicknesses

Different resin systems (polyester, vinyl ester, epoxy)

Custom colors & finishes

This adaptability allows engineers to tailor tubes for specific project needs.

2.5 Low Maintenance & Long Lifespan

Unlike metals, fiberglass does not require:

Galvanizing or painting

Frequent inspections for rust

Chemical coatings

With minimal upkeep, FRP tubes can last decades, reducing lifecycle costs.

3. Industrial Applications of Fiberglass Rectangular Tubes

3.1 Construction & Infrastructure

Structural framing (lightweight alternative to steel)

Bridge components (corrosion-resistant decking & supports)

Architectural cladding & facades

3.2 Chemical & Industrial Processing

Chemical storage supports

Piping & ventilation systems

Scrubbers & exhaust stacks

3.3 Marine & Offshore

Boat frames & docks

Offshore platform walkways

Saltwater-resistant railings

3.4 Electrical & Telecommunications

Cable trays & ladder systems

Transformer supports

Antenna masts

3.5 Renewable Energy

Solar panel mounting structures

Wind turbine components

Hydroelectric plant reinforcements

3.6 Transportation & Automotive

Truck & trailer flooring

Railway components

Aerospace interior structures

4. Fiberglass vs. Steel vs. Aluminum: A Comparison

| Property | Fiberglass Tubes | Steel Tubes | Aluminum Tubes |

| Weight | Very Light | Heavy | Moderate |

| Corrosion Resistance | Excellent | Poor (rusts) | Moderate (oxidizes) |

| Electrical Conductivity | Non-Conductive | Conductive | Conductive |

| Maintenance | Low | High | Moderate |

| Cost Over Time | Lower (long lifespan) | Higher (rust repairs) | Moderate |

Conclusion: For long-term durability in corrosive environments, fiberglass rectangular tubes outperform metals.

5. Future Trends in Fiberglass Rectangular Tubing

Increased use in green building projects (LEED-certified constructions)

Advancements in fire-resistant FRP formulations

3D-printed custom fiberglass profiles for specialized applications

Conclusion

Fiberglass rectangular tubes offer unmatched corrosion resistance, strength, and versatility, making them a superior alternative to traditional metal tubes. From construction and marine applications to electrical and renewable energy projects, their benefits ensure long-term performance with minimal maintenance.

As industries still place a premium on sturdiness, property, and cost-efficiency, fiberglass rectangular tubes can remain an important material in fashionable engineering and infrastructure development