What are the disadvantages of fiberglass rebar?

Fiberglass reinforced polymer (FRP) rebar, commonly known as fiberglass rebar or GFRP (Glass Fiber Reinforced Polymer) rebar, has rapidly gained traction as a compelling alternative to traditional steel reinforcement in concrete. Touted for its exceptional corrosion resistance, lightweight properties, and electromagnetic transparency, it has found widespread application in aggressive environments and specialized structures. However, a balanced understanding of any construction material requires acknowledging its limitations. While fiberglass rebar offers significant advantages in specific scenarios, it also presents distinct disadvantages that engineers, contractors, and project managers must meticulously consider before specifying its use.

This comprehensive analysis delves into the critical drawbacks of fiberglass rebar, exploring its performance characteristics, installation complexities, economic implications, and design considerations where it may fall short compared to conventional steel rebar.

The Nuance of Choice: Understanding Fiberglass Rebar's Limitations

While the benefits of fiberglass rebar are well-publicized, its disadvantages are equally important for informed decision-making in concrete construction. These limitations often stem from its fundamental material properties as a composite and its departure from the ductile behavior characteristic of steel.

1. Lower Modulus of Elasticity (Stiffness) and Increased Deflection

This is arguably the most significant engineering challenge associated with fiberglass rebar.

What it means: The "modulus of elasticity" (or Young's modulus) is a measure of a material's stiffness or resistance to elastic deformation under stress. Steel rebar has a very high modulus of elasticity (approximately 200 GPa). Fiberglass rebar, on the other hand, has a significantly lower modulus, typically ranging from 45 GPa to 60 GPa, which is roughly one-quarter to one-third that of steel.

The implication for concrete: This lower stiffness means that for the same applied load, a concrete element reinforced with fiberglass rebar will experience greater deflection and wider crack widths compared to an identical element reinforced with steel. While GFRP rebar boasts higher tensile strength (the ultimate load it can carry before breaking) than steel, its lower stiffness can lead to serviceability issues, such as excessive cracking and deflections that are visually unappealing or compromise the integrity of non-structural elements (e.g., floor finishes, partitions).

Design implications: To mitigate these issues, engineers often need to use a higher reinforcement ratio (more GFRP rebar) or larger bar diameters when designing with fiberglass rebar to achieve comparable stiffness and control crack widths to acceptable levels. This can partially offset the weight savings and, in some cases, the cost benefits. Some designs might require up to 30-40% more GFRP rebar to meet deflection standards. A lack of understanding of this fundamental difference has historically led to structural failures, such as reported severe cracking and excessive deflections in structures where GFRP was under-reinforced.

2. Brittle Failure and Lack of Ductility

This is another critical difference from steel and a major concern in seismic or dynamic loading applications.

What it means: Steel rebar is a ductile material. When subjected to excessive tensile forces, it exhibits a significant "yield" phase, meaning it deforms plastically and stretches considerably before fracturing. This ductile behavior provides a visible warning of impending failure, allowing occupants to evacuate and engineers to intervene.

The implication for concrete: Fiberglass rebar is a linear elastic material until fracture, meaning it does not yield or deform plastically. It fails suddenly and catastrophically once its ultimate tensile strength is reached, with little to no visible warning. This "brittle failure" mode is undesirable in many structural applications, particularly in seismic zones or structures designed to absorb significant energy from dynamic loads (e.g., traffic barriers, industrial floors).

Design implications: Building codes and design philosophies for reinforced concrete heavily rely on the ductility of steel rebar to dissipate energy during events like earthquakes. Designing with GFRP rebar requires careful consideration to ensure that the concrete's compressive failure (a more ductile mode) occurs before the brittle rupture of the GFRP. This often necessitates conservative design approaches and higher safety factors (e.g., ACI 440 design codes may require a safety factor of 2.5 for GFRP compared to 1.67 for steel) which can reduce the perceived advantages in weight and cost.

3. Higher Upfront Material Cost

While fiberglass rebar offers long-term lifecycle cost advantages in corrosive environments, its initial material cost is typically higher than that of conventional steel rebar.

Cost disparity: Depending on the market, bar size, and supplier, GFRP rebar can cost anywhere from 15% to 150% more per linear foot than standard black steel rebar. For instance, while basic steel rebar might range from $0.40 to $1.25 per linear foot, fiberglass rebar could be $0.65 to $2.50 per linear foot or even higher for specialized types.

Project impact: For projects where corrosion resistance is not a primary concern, or where budget constraints are extremely tight, the higher initial material cost of fiberglass rebar can be a significant deterrent, potentially making steel rebar the more economically viable choice for the short term. The perception of higher cost can also be a barrier to wider adoption, even when lifecycle cost savings are demonstrably higher.

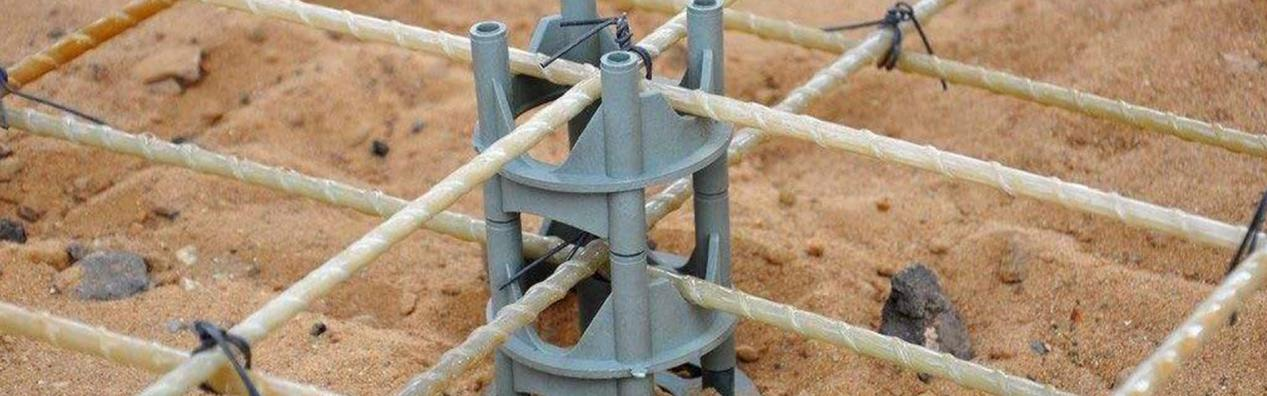

4. Inability to Bend On-Site and Fabrication Constraints

The manufacturing process and material nature of fiberglass rebar impose strict limitations on its field fabrication.

No field bending: Unlike steel rebar, which can be easily bent on-site using rebar benders to accommodate design changes or specific structural geometries, fiberglass rebar cannot be bent in the field. Attempting to bend a cured GFRP bar will cause internal micro-fractures in the composite matrix, severely compromising its structural integrity and potentially leading to premature failure.

Pre-fabrication required: All necessary bends, hooks, stirrups, and complex shapes must be pre-fabricated at the factory using specialized heat-forming processes before the GFRP bars are delivered to the construction site. This requires meticulous planning, precise detailing in design, and longer lead times for ordering custom shapes. Any errors in design or unexpected field conditions that necessitate bending can lead to costly delays and waste.

Cutting limitations: While fiberglass rebar can be cut on-site, it requires specific tools (e.g., diamond-blade saws or abrasive cut-off saws) and personal protective equipment (PPE) to prevent inhalation of fiberglass dust and skin irritation. Standard rebar cutters used for steel are unsuitable.

5. Lower Shear Strength and Bond Characteristics

Shear strength: Fiberglass rebar generally exhibits lower shear strength compared to steel rebar. This can limit its use in structural components where high shear resistance is required, such as in heavily loaded beams or columns without adequate stirrup reinforcement.

Bond with concrete: While GFRP rebar is manufactured with ribbed or sand-coated surfaces to enhance its mechanical bond with concrete, its bond characteristics can differ from steel, particularly under sustained loads or in dynamic conditions. Some research indicates that the bond performance may require specific design considerations to ensure reliable load transfer, and special anchoring designs might be needed.

6. Performance at High Temperatures and Fire Resistance

Resin degradation: The polymer resin matrix in fiberglass rebar is susceptible to degradation at elevated temperatures. Typically, at temperatures above approximately 300°C (572°F), the resin begins to soften, and the mechanical properties (strength and stiffness) of the GFRP rebar can significantly degrade. While the concrete cover provides some insulation, in severe fire events, the internal temperature of the rebar can reach critical levels.

Brittleness in cold temperatures: Some types of GFRP rebar can also exhibit increased brittleness at extremely low temperatures, although this is less common for standard construction applications.

Design implications: For structures where fire safety is a primary concern or where a high fire rating is mandated, special protective measures or increased concrete cover might be necessary when using GFRP rebar. This can complicate design and potentially add to costs, especially when compared to steel rebar which maintains a higher percentage of its strength at elevated temperatures, albeit still degrading.

7. Limited Standardization and Industry Familiarity

Evolving codes: While significant progress has been made, the adoption of fiberglass rebar is still relatively new compared to steel, which has a century of established design codes, standards, and practical experience. Although comprehensive guidelines like those from the American Concrete Institute (ACI) Committee 440 exist, widespread familiarity and acceptance among all engineers, architects, and local building officials are still developing.

Design complexity: Designing with GFRP rebar often requires a deeper understanding of composite material behavior and specific design methodologies to account for its lower stiffness, brittle failure mode, and bond characteristics. This can be a learning curve for some designers accustomed to traditional steel reinforcement.

Quality control: Ensuring consistent quality control for GFRP rebar can be more complex than for steel, given the varied manufacturing processes and resin/fiber combinations.

8. Challenges with Recycling and Sustainability at End-of-Life

Non-recyclable through traditional means: While fiberglass rebar offers environmental benefits in terms of production carbon footprint and extended service life, its composite nature makes it difficult to recycle using conventional methods. The thermoset resins used in GFRP are typically not meltable or easily separated from the glass fibers.

End-of-life disposal: Currently, a significant portion of end-of-life GFRP products (including turbine blades, which are predominantly fiberglass) ends up in landfills. Research into advanced recycling technologies (e.g., pyrolysis, solvolysis, mechanical grinding for use as filler) is ongoing, but commercial viability at scale is still developing. This contrasts with steel, which is highly recyclable and has a well-established recycling infrastructure.

9. Punching Shear and Connection Design

Lower transverse strength: The nature of pultruded GFRP rebar, with fibers primarily oriented longitudinally, means it typically has lower transverse (perpendicular to the bar axis) shear strength compared to steel. This can be a consideration in designs involving punching shear around columns or concentrated loads.

Complex connections: Designing connections and anchorage zones for GFRP rebar can be more complex due to its material properties. Special non-metallic couplers and anchoring systems are required, as traditional welding or standard mechanical splices used for steel are not applicable.

Real-World Implications and Informed Decision-Making

The disadvantages of fiberglass rebar highlight that it is not a universally superior material, but rather a specialized solution. Its selection should be a deliberate and informed choice, not a default replacement for steel.

Application-specific: For projects in highly corrosive environments (marine structures, chemical plants, de-icing salt-affected roads), the long-term benefits of GFRP rebar's corrosion resistance often outweigh its disadvantages, making it the preferred and ultimately more economical solution.

Seismic Zones: In high seismic zones, the brittle nature of GFRP rebar requires engineers to implement more conservative design strategies or consider hybrid reinforcement systems (combining steel and GFRP) to ensure the necessary ductility for energy dissipation during an earthquake.

Economic Analysis: A thorough lifecycle cost analysis is crucial. While upfront material costs for GFRP may be higher, reduced maintenance and extended service life can lead to significant savings over the project's lifespan, especially for critical infrastructure.

Designer Expertise: The successful implementation of fiberglass rebar relies heavily on the expertise of structural engineers who are familiar with its unique mechanical properties, design codes (e.g., ACI 440), and the implications of its lower stiffness and brittle failure.

Conclusion: A Material with Specific Strengths and Weaknesses

Fiberglass rebar has undoubtedly carved out a vital niche in modern concrete construction, offering unparalleled advantages in corrosive and electromagnetically sensitive applications. However, to leverage its strengths effectively and avoid potential pitfalls, it is imperative to acknowledge and mitigate its disadvantages.

Its lower modulus of elasticity, leading to increased deflections and crack widths, its brittle failure mode, higher upfront cost, and the inability to bend on-site are significant considerations that demand careful design, planning, and execution. As the construction industry continues to innovate, ongoing research aims to address some of these limitations, with advancements in fiber types, resin systems, and hybrid composite solutions.

Ultimately, the choice between fiberglass and steel rebar is not a simple "better or worse" proposition. It's a strategic decision that hinges on a meticulous evaluation of the project's specific environmental conditions, structural demands, aesthetic requirements, economic parameters, and the expertise available. By understanding both the compelling advantages and the inherent disadvantages, construction professionals can make informed choices, ensuring the creation of resilient, durable, and cost-effective concrete structures for the future.