The Versatile Powerhouse: A Comprehensive Guide to Where You Can Use Fiberglass Rods

Introduction: The Unseen Backbone of Modern Industry

Look around you. In the walls of your home, the car you drive, the energy that powers your city, and even in the tools for your favorite hobby, there's a high chance a fiberglass rod is playing a critical role. Often overshadowed by its more glamorous cousin, carbon fiber, the fiberglass rod is a workhorse of modern engineering. But what exactly is it, and where can we use fiberglass rods to their full potential?

This comprehensive guide will dive deep into the myriad applications of this versatile material. We'll explore why its unique properties—exceptional strength-to-weight ratio, corrosion resistance, and electrical non-conductivity—make it indispensable across dozens of fields. Whether you're an industry professional, an avid angler, or a weekend DIYer, understanding the uses of fiberglass rods can open up a world of possibilities.

What is a Fiberglass Rod? A Primer

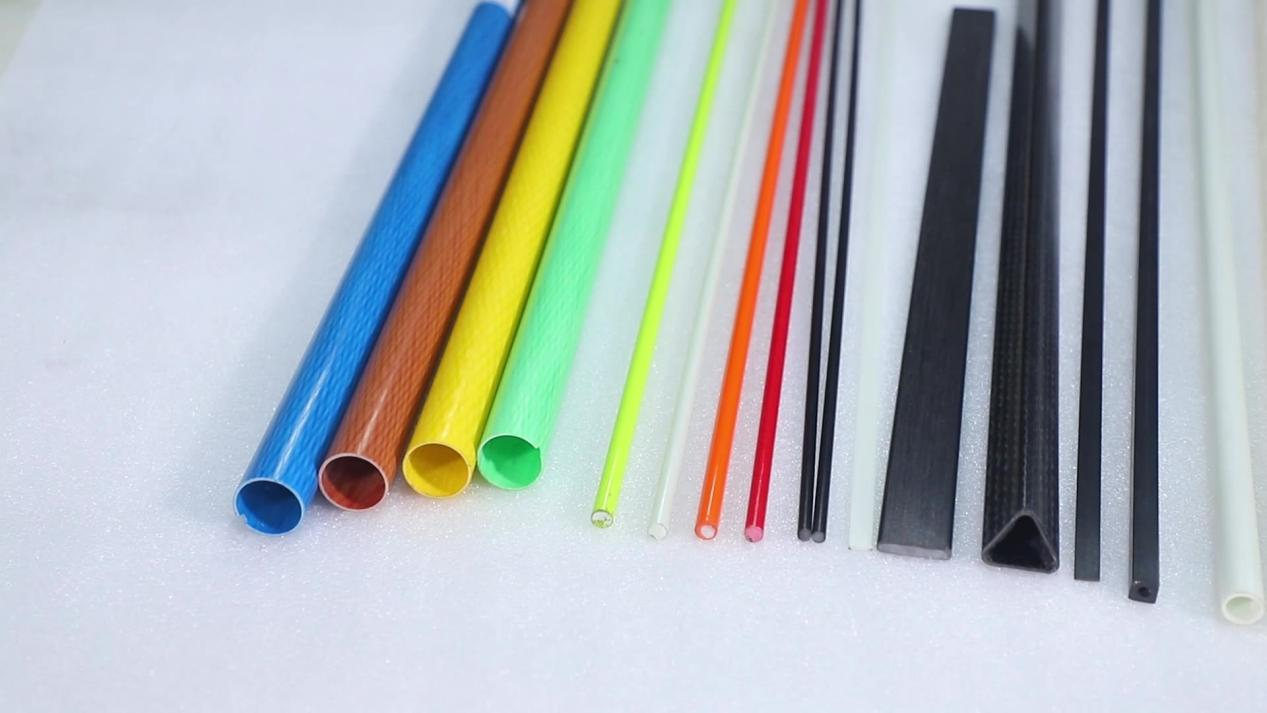

Before we explore its uses, let's quickly define what we're talking about. A fiberglass rod is a composite material made by drawing out glass into extremely fine fibers. These fibers are then woven into a fabric and saturated with a plastic resin, such as epoxy or polyester. The mixture is then cured, often under heat and pressure, to form a rigid, incredibly strong, and lightweight rod.

The key advantages that fuel its versatility are:

--High Strength & Lightweight: Fiberglass offers a superior strength-to-weight ratio compared to steel and many other metals.

--Corrosion Resistance: It does not rust or corrode when exposed to moisture, chemicals, or harsh environmental conditions.

--Electrical Insulation: Being non-conductive, it is perfectly safe for use around live electrical components.

--Durability: It has excellent fatigue resistance and can flex repeatedly without breaking.

--Design Flexibility: It can be manufactured in various diameters, lengths, and shapes to meet specific needs.

Now, let's journey through the industries where these properties make all the difference.

1. Construction and Infrastructure: Building a Stronger Future

The construction industry is one of the largest consumers of fiberglass rods. Their non-corrosive nature is a game-changer for concrete structures.

Concrete Reinforcement (Rebar): In environments where corrosion is a primary concern—such as marine structures, bridges, roadways, and parking garages—fiberglass rebar is replacing traditional steel. It prevents the unsightly and structurally damaging "concrete cancer" caused by rusting steel.

Scaffolding and Framing: Fiberglass poles and platforms are used for scaffolding, especially near power lines or in chemical plants, where their non-conductive and corrosion-resistant properties are critical for worker safety.

Measuring Tools: The ubiquitous fiberglass tape measure is a classic example. It's durable, flexible, and won't stretch or conduct electricity, making it safer for construction sites.

2. The Utility and Energy Sector: Powering the World Safely

Safety is paramount in the utility sector, and fiberglass rods are at the forefront.

Hot Sticks: Linemen and utility workers use fiberglass hot sticks for live-line working. These insulated tools allow them to safely handle, test, and repair high-voltage power lines without de-energizing them, preventing costly blackouts.

Antenna and Mast Systems: For communication towers, ham radio operators, and CCTV installations, fiberglass masts are ideal. They are lightweight, strong, and radio-transparent, meaning they don't interfere with signal transmission.

Oil & Gas Industry: Used for level gauges, sediment gauges, and cleaning rods in tanks and pipes, fiberglass will not spark, making it safe in volatile, explosive environments.

3. Telecommunications: Connecting the Globe

The demand for faster, more reliable data is relentless, and fiberglass rods play a supporting role.

Fiber Optic Cable Strengthening Members: The very cables that deliver your internet and phone service often have a fiberglass rod, known as a GRP (Glass Reinforced Plastic) rod, at their core. This "strength member" provides tensile strength, protecting the delicate glass fibers inside from stretching and breaking during installation and throughout their lifespan.

4. Transportation and Aerospace: Lightweighting for Efficiency

In automotive, aerospace, and marine industries, reducing weight directly translates to better fuel efficiency and performance.

Aerospace: Fiberglass rods are used in various non-critical structural components, interior panels, and insulation supports in aircraft.

Automotive: They can be found in antenna systems, as structural supports for interior trim, and in various components where a strong, lightweight, and non-corrosive material is needed.

Marine: From boat spars and outriggers to structural elements in small watercraft, fiberglass's resistance to saltwater corrosion makes it a perfect fit for the marine environment.

5. Consumer Goods and Recreation: Enhancing Everyday Life

This is where most people encounter fiberglass rods directly.

Fishing Rods: This is one of the most well-known applications. Fiberglass fishing rods are prized for their durability, flexibility, and lower cost compared to carbon fiber models, making them excellent for beginners and specific fishing techniques.

Tent Poles: The flexibility and strength of fiberglass make it the material of choice for tent poles in camping gear. They can withstand strong winds and repeated setup/takedown without failing.

Kite Frames: For stunt kites and larger parafoils, fiberglass rods provide the perfect blend of stiffness and flex.

Model and Hobby Building: DIY enthusiasts and model makers use thin fiberglass rods for reinforcement in projects ranging from model airplanes to custom cosplay costumes.

6. Agriculture and Horticulture: Supporting Growth

The agricultural sector utilizes fiberglass for its durability and weather resistance.

Plant Stakes and Trellises: Fiberglass rods are an excellent alternative to wood or bamboo for supporting tomatoes, vines, and other plants. They do not rot, splinter, or degrade in the soil, lasting for many seasons.

Greenhouse Framing: The frames of many greenhouses are made from fiberglass, as they resist the constant humidity and chemical exposure from fertilizers and pesticides better than metal.

7. Specialized and Niche Applications

The uses for fiberglass rods are limited only by imagination.

Medical Devices: Used in certain types of splints, orthopedic devices, and supports where a lightweight, radiolucent (transparent to X-rays) material is required.

Cleaning and Maintenance: Long fiberglass rods are used with attachments to clean drains, ducts, and pipes that are difficult to access.

Flagpoles: Lightweight and never needing a paint touch-up, fiberglass flagpoles are a low-maintenance option for homes and businesses.

Conclusion: The Indispensable, Invisible All-Rounder

From the depths of the ocean to the heights of communication towers, and from the power grid to your backyard garden, the fiberglass rod is a testament to how a simple composite material can revolutionize countless industries. Its unique combination of strength, lightness, durability, and safety makes it an often unseen but absolutely indispensable component of modern life.

The next time you reel in a fish, measure a wall, or simply use the internet, take a moment to appreciate the humble fiberglass rod—the versatile powerhouse working behind the scenes.

Contact Us:

Add: Northwest of Damotan, Tianma Village, Xiema Street, Beibei District, Chongqing, P.R.China

Web: www.cqdjfrp.com

Email: [email protected] /[email protected]

WhatsApp: +8615823184699

Tel:+86-023-67853804