How strong is fiberglass tubing?

Subtitle: It’s not about matching steel pound-for-pound. Discover the unique strength profile that makes fiberglass tubing the superior choice in countless demanding applications.

When engineers and designers hear "fiberglass tubing," thoughts often drift to hobbyist projects or lightweight tents. But this perception belies a startling reality. The question "How strong is fiberglass tubing?" is one of the most critical in modern materials engineering. The answer isn't a single number but a revelation of a unique strength profile that often outperforms traditional metals in the most challenging environments.

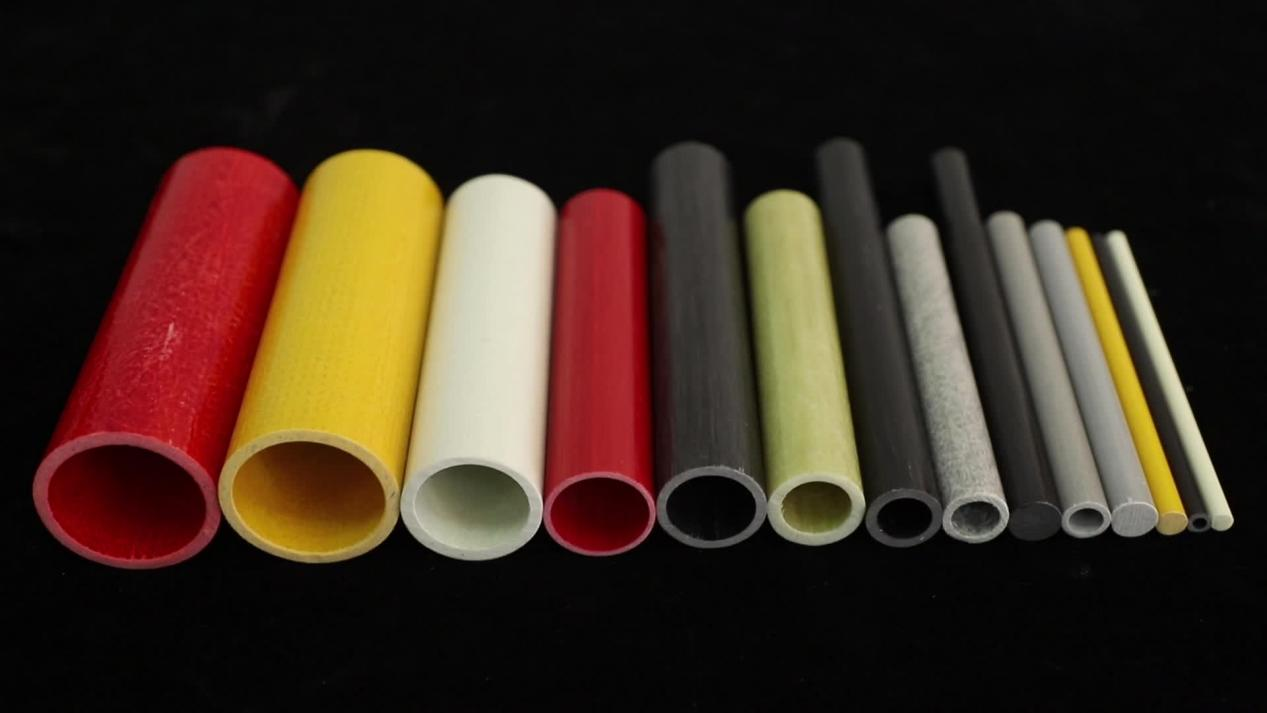

Fiberglass tubing, more accurately known as Fiber-Reinforced Polymer (FRP) tubing, is a composite material. Its strength doesn't come from a homogeneous metal grain but from a sophisticated synergy: millions of microscopic glass fibers embedded in a protective polymer resin matrix. This composite structure is the source of its remarkable and often misunderstood capabilities.

Let's dismantle the myths and quantify the true strength of fiberglass tubing.

Deconstructing Strength: The Four Pillars of FRP Performance

To understand fiberglass tubing, we must look at strength through multiple lenses.

1. Tensile Strength: The Pull of Power

Tensile strength measures a material's resistance to being pulled apart.

How Strong is It? High-quality fiberglass tubing can have a tensile strength ranging from 30,000 to 100,000 psi and beyond, depending on the fiber orientation and resin type. This places it firmly in the same league as many structural steels.

The Key Differentiator: While a steel tube might have a higher absolute tensile strength, fiberglass has a much higher specific strength (strength-to-weight ratio). A fiberglass tube can match the tensile load capacity of a steel tube while weighing up to 70% less. This is a critical advantage in applications like aerospace, automotive, and portable equipment.

2. Flexural Strength: Resistance to Bending

Flexural strength indicates how well a fiberglass tube can withstand bending forces before it yields or breaks.

How Strong is It? Fiberglass tubing excels here, with flexural strength values typically between 20,000 and 70,000 psi. The composite structure allows it to flex and recover without permanent deformation, a property known as high flexural modulus.

The Key Differentiator: Unlike brittle materials, well-designed FRP tubing can absorb significant impact energy by flexing, making it excellent for applications like push rods, antennae, and structures in high-wind areas.

3. Compressive Strength & Crush Resistance

This measures the frp tube's ability to withstand a crushing or compressive load.

How Strong is It? This is one area where solid steel generally has a higher absolute value. The compressive strength of fiberglass tubing is still substantial, often in the 15,000 to 30,000 psi range, but it is more susceptible to failure modes like buckling if not properly supported.

The Key Differentiator: For most structural applications where loads are a mix of tension, compression, and bending, the compressive strength of fiberglass is more than adequate. Its performance is enhanced by its stiffness and light weight, which reduce the overall load on the structure.

The Secret Weapons: Where Fiberglass Tubing Truly Dominates

The raw numbers only tell half the story. Fiberglass tubing's real strength lies in properties that metals struggle to match.

Corrosion Resistance: The Unbeatable Champion

This is arguably fiberglass's greatest strength. It is impervious to rust and highly resistant to a vast range of chemicals, salts, and acidic or alkaline environments. A fiberglass tube supporting a load in a chemical plant or off a coastal pier will outlast and outperform a steel tube of equivalent size that would corrode and weaken rapidly. In this context, its long-term strength retention is superior.

Fatigue Strength: The Endurance Athlete

Fatigue strength is the ability to withstand repeated loading and unloading. Steel has a well-defined fatigue limit, but fiberglass's composite nature allows it to endure a high number of stress cycles without cracking. This makes it ideal for applications involving vibration, such as in automotive components or machinery.

Dielectric Strength: The Insulating Power

Fiberglass is an excellent electrical insulator. This "strength" is not mechanical but is a critical safety and performance feature. It is the material of choice for live-line tools used by utility workers, ladder rails, and electrical enclosures, where any electrical conductivity from a material like aluminum or steel would be catastrophic.

Head-to-Head: Fiberglass vs. Traditional Materials

Let's compare fiberglass tubing directly with its metal counterparts in a practical context.

| Property | Fiberglass Tubing | Steel Tubing | Aluminum Tubing |

| Tensile Strength | High | Very High | Medium-High |

| Specific Strength | Exceptional | Low | High |

| Corrosion Resistance | Exceptional | Very Poor | Good (but can pit) |

| Weight | Very Low | Very High | Low |

| Electrical Insulation | Excellent | Conductive | Conductive |

| Thermal Expansion | Low | Medium | High |

| Ease of Fabrication | High (can be cut, drilled) | Medium | High |

As the table shows, fiberglass doesn't "win" in every single category, but it offers a unique and powerful combination of properties that no metal can match.

Real-World Applications: Strength in Action

The theoretical strength of fiberglass tubing is proven daily in demanding fields:

Electrical & Utility: Ladder rails, hot sticks, conduit, and antennae leverage its dielectric strength and corrosion resistance.

Chemical & Water Processing: Handrails, walkways, pipe supports, and scrubber components withstand harsh fumes and spills that would decimate steel.

Oil & Gas: Sucker rods used in pumping units are lightweight, reducing energy costs, and are immune to downhole corrosion.

Marine & Offshore: Boat masts, railings, and structural components do not rust in saltwater, eliminating constant maintenance.

Aerospace & Automotive: Lightweight structural frames and push rods benefit from the high strength-to-weight ratio, improving fuel efficiency and performance.

Conclusion: Redefining "Strength" for the Modern Age

So, how strong is fiberglass tubing?

The answer is: It is strong enough to replace steel in countless applications, while offering a decisive advantage in weight, corrosion resistance, and design flexibility. Its strength is not a single metric but a multifaceted capability profile.

When your design requirements involve one or more of the following:

--A corrosive environment

--A critical need for weight reduction

--Electrical insulation

--High fatigue or impact resistance

...then fiberglass tubing isn't just a strong alternative; it is often the strongest possible choice when considering total lifecycle cost, safety, and performance. It’s a testament to the fact that in engineering, true strength is about having the right properties for the challenge at hand.

Before specifying your next project, consult with a fiberglass tubing specialist. They can help you select the right resin system and fiber orientation to tailor the strength profile precisely to your needs, unlocking the silent power of this composite giant.