Fiberglass Rod vs. Carbon Fiber: Which One is Right for Your Project?

In the world of high-performance composite materials, two titans dominate the market: Fiberglass Rods and Carbon Fiber Rods. To the untrained eye, they might look similar, but in the realm of structural engineering, industrial manufacturing, and high-end DIY, choosing the wrong one can lead to catastrophic failure or unnecessary overspending.

As we move into 2025, the demand for lightweight, corrosion-resistant materials is skyrocketing. This comprehensive guide breaks down the "Fiberglass vs. Carbon Fiber" debate to help you determine which material will deliver the best ROI for your specific application.

1. The Structural DNA: Strength vs. Stiffness

The most fundamental difference lies in their mechanical properties.

Carbon Fiber Rods are the champions of stiffness-to-weight ratio. Utilizing tightly woven carbon atoms, these rods offer incredible tensile strength and a high modulus of elasticity. If your project requires a material that will not bend under immense pressure (zero deflection), carbon fiber is the gold standard.

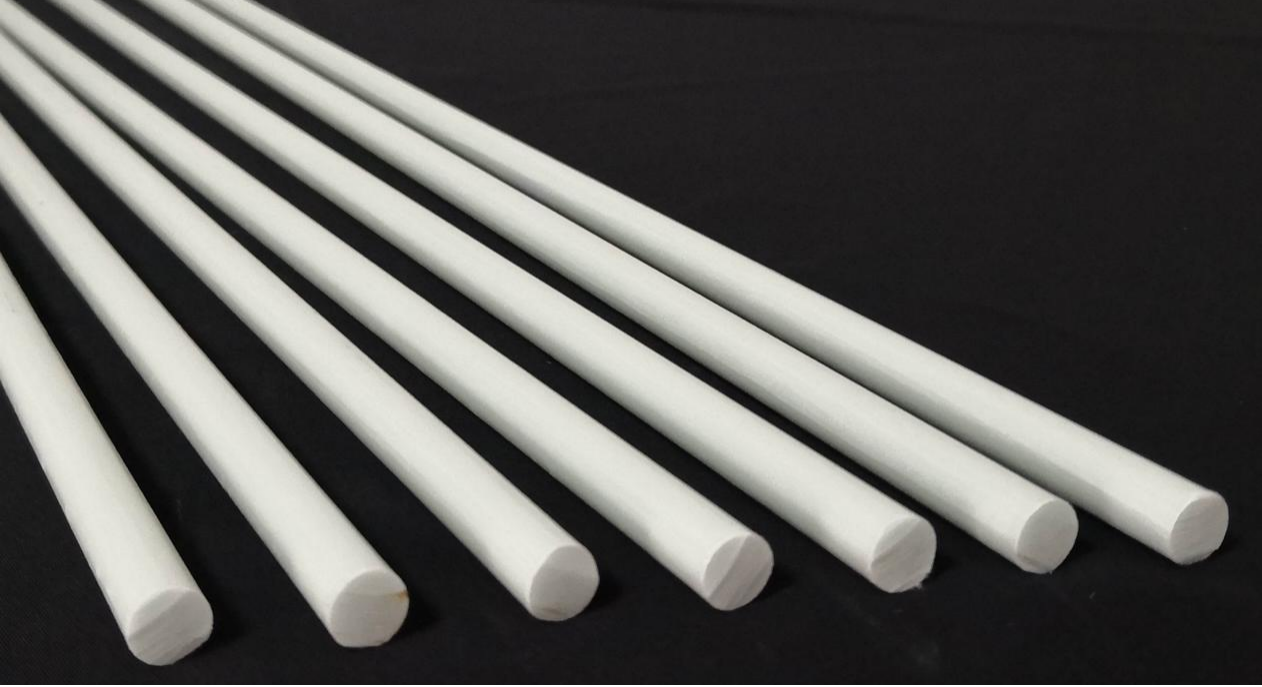

Fiberglass Rods, particularly those made via the pultrusion process, are known for their resilience and flexibility. While they have lower stiffness (Young’s Modulus) than carbon fiber, they can absorb significant impact energy without fracturing.

The "Snap" Test: When pushed beyond its limit, carbon fiber tends to shatter or splinter catastrophically. Fiberglass, conversely, is more "forgiving," often bending significantly before any structural compromise occurs.

2. Weight Dynamics: When Every Gram Counts

If your application is for the aerospace, drone manufacturing, or high-performance cycling industries, weight is likely your primary KPI.

Carbon fiber is approximately 20% to 30% lighter than fiberglass. Its lower density allows engineers to design structures that are incredibly rigid yet light enough to be propelled with minimal energy.

However, for ground-based infrastructure—such as utility pole markers, greenhouse frames, or garden stakes—the marginal weight savings of carbon fiber rarely justify the cost. In these cases, the slightly heavier fiberglass rod provides the necessary "heft" and stability at a fraction of the price.

3. Conductivity and Signal Interference: The Hidden Decider

One of the most overlooked factors in material selection is electrical conductivity.

Carbon Fiber is conductive. This makes it unsuitable for applications near high-voltage power lines, electrical enclosures, or as antenna supports, as it can cause short circuits or signal interference.

Fiberglass is a superior insulator. It is non-conductive and transparent to radio frequencies (RF). This is why fiberglass rods are the industry standard for electrical duct rodders, ladder rails, and telecommunications towers.

Pro Tip: If your project involves electrical environments or GPS/WiFi signals, fiberglass is not just the cheaper choice—it is the safer, more functional choice.

4. Corrosion Resistance and Environmental Durability

Both materials outperform traditional steel and wood in harsh environments, but they react differently to external stressors:

Chemical Resistance: Fiberglass rods are exceptionally resistant to acids, salts, and alkalis. This makes them ideal for wastewater treatment plants and marine moorings.

Thermal Expansion: Carbon fiber has a near-zero coefficient of thermal expansion. It remains dimensionally stable even in extreme temperature swings. Fiberglass expands and contracts slightly more, though still far less than aluminum or steel.

UV Exposure: Raw fiberglass can degrade under intense sunlight (fiber blooming). However, high-quality modern fiberglass rods are manufactured with UV-inhibitors and polyester veils that allow them to last 20+ years outdoors.

5. The Economic Reality: Cost vs. Value

Let’s talk about the bottom line. Fiberglass rods are significantly more cost-effective.

The raw materials and the energy-intensive manufacturing process required for carbon fiber drive its price 5 to 10 times higher than fiberglass. For large-scale industrial projects—such as bridge reinforcement or agricultural fencing—the cost difference can amount to tens of thousands of dollars.

Choose Fiberglass when:

You need bulk quantities.

The project requires high impact resistance and flexibility.

Non-conductivity is a requirement.

Budget efficiency is a priority.

Choose Carbon Fiber when:

Extreme rigidity and "zero-flex" are mandatory.

Weight reduction is the most critical factor (e.g., robotics).

High-end aesthetics (the classic "carbon weave" look) are desired.

Conclusion: Which One Should You Buy?

There is no "better" material—only the right material for the job. Carbon fiber is a specialized "Formula 1" material designed for peak performance where cost is no object. Fiberglass is the "workhorse" of the modern industry—versatile, rugged, and economically smart.

For 90% of industrial and commercial applications, Fiberglass rods provide the perfect balance of durability and affordability.

Need a Custom Solution?

At CQDJ, we specialize in high-quality pultruded fiberglass rods tailored to your exact specifications. Whether you need custom diameters, UV-resistant coatings, or specific flex-strengths, our team is here to help.

Would you like us to send you a free sample pack of our fiberglass rods to test against your current materials? [Click here to request a sample]