Fiberglass For Concrete There are many reasons that fiberglass concrete reinforcement is as important to building strong buildings as steel reinforcing. CQDJ focuses on this novel approach for enhancing the strength of concrete. A lightweight alternative to traditional steel channels or bars and mesh is fiberglass. This novel method for strengthening concrete could help buildings, bridges and other structures - including nuclear facilities - to stand up better to aging and resist damage. It works well for spaces exposed to extreme weather, say heavy rain or high winds. Being made of fiberglass, you can also make a structure that is lighter; this comes in handy when building big projects. For more information on the advantages of using fiberglass, check out Fiberglass utility poles: Benefits, uses, and top manufacturers.

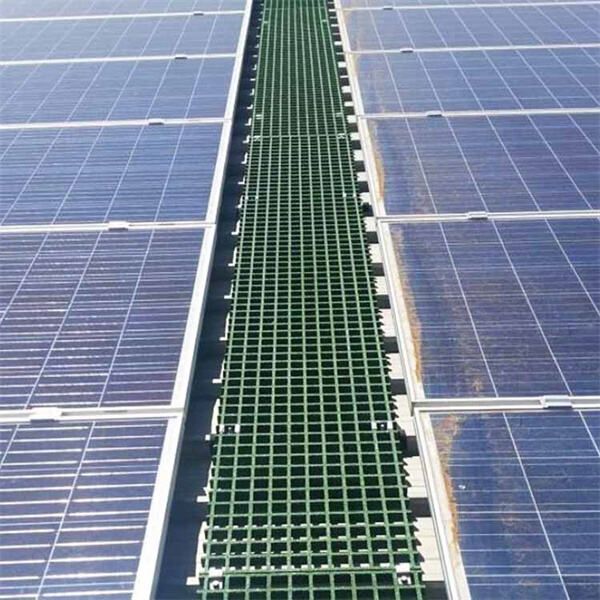

Benefits of fiberglass reinforcement versus conventional steel application. For one thing, fiberglass weighs a lot less than steel. This makes it more convenient to carry, and take to work sites. Construction workers can simply lift it, without heavy machinery, which saves time and energy. Moreover, fiberglass does not corrode the way steel does. In areas where water is abundant, such as near lakes or oceans, fiberglass can be a tool in avoiding damage by rust. That’s less maintenance in the long run. Traditional steel reinforcement can be strong, but it may also cause problems if it gets wet, which can make concrete crack. Fiberglass helps avoid this issue. It also has a high strength-to-weight ratio, so it can hold a ton of weight without being too heavy. “It is light and strong, so a material can be very thin without being structurally weak,” he said via email.“That’s ideal for things like bridges, which need to hold up the weight of dozens of cars but also not get too heavy themselves.” Finally, fiberglass can be more easily molded into various shapes than steel. This can yield to more imaginative styling in building designing, which would not be with the use of standard steel re-bars. CQDJ is excited to be at the forefront of advances in fiberglass as a means for reinforcing concrete and demonstrating how tools like ecoQ can improve construction methods. Additionally, for customizable applications, consider exploring Fiberglass Molded Grating Customizable Solutions.

Although there are many positive aspects of using fiberglass reinforcement, there are also challenges that arise for the user. One potential downside is that fiberglass can be more expensive initially than your typical steel door. Builders may be resistant to try the fiberglass because they are not used to it, or fear it could be more expensive. But when you factor in the longer-term benefits, including the savings on maintenance and their enhanced durability, it can be worth it. Also there is no guarantee that all workers will know how to handle fiberglass. It is important for training and education so that everyone knows how to install it appropriately. When not done effectively, however, the advantages of fiberglass may not be maximized. And fiberglass can be susceptible to the damage of some chemicals, which eventually may weaken it. What products used around it may affect its color? Last, perhaps some people are concerned about what fiberglass is like in very cold or very hot temperatures. It must be tested to verify that the fiberglass reinforcement is capable of maintaining its integrity under the pertinent conditions. CQDJ is committed to assisting customers in understanding these challenges and offering optimal technical support for the application of FRP reinforcement.

Fiberglass reinforced concrete has many advantages, it's just plain smart! First, let’s establish what fiberglass is. Fiberglass is a sturdy product composed of very small fibers made out of glass. Mixed with concrete, it makes concrete stronger and last longer. This is significant because concrete is found in millions of buildings, roads and bridges. Fiberglass when used to reinforce concrete, makes it more impervious to cracks and will also not break. That means the structures constructed with this kind of concrete can support heavy loads and resist bad weather. It also leads to fewer dollars spent on repairs in the long run. People who create things like to have them last, and fiberglass can make that happen.

Reason number two that fiberglass concrete reinforcement is an intelligent choice also has to do with weight! This makes it more manageable and transportable than other materials, such as steel. This can be a cost- and time-saver during construction. The ability to move and put down fiberglass reinforcement on a project rapidly helps builders finish projects faster. Futhermore fiberglass does not rust as steel will. This is a good thing, since rust weakens over time and is often followed by other problems. Making use of fiberglass ensures that the concrete remains strong and safe for many years to come. Finally, fiberglass may be cheaper over time. Although it may be a bit more expensive initially, the savings on repairs and maintenance can really add up. Overall, if you’re building, fiberglass concrete reinforcement is a smart call.

CQDJ is a good source if you want to purchase fiberglass concrete reinforcement. They tend to be relatively inexpensive and can give you large amounts if that’s what you need. Owning in bulk is wise because you will be cost effective over time. Many companies offer discounts when you buy larger quantities, so that you pay less per piece. This is particularly helpful for builders with large or multiple projects at once. CQDJ knows what the customers want and supplies several good kinds of fiberglass products for you. There are many different sizes and types of fiberglass reinforcement available to builders so that they may select the proper size for their project.

Beyond that, the future of fiberglass concrete reinforcement is very promising with new developments. Some companies, CQDJ included, are constantly striving to improve their products. One area ripe for innovation is in the invention of new forms of fiberglass, stronger and more bombproof than ever. These new materials could help buildings and roads survive longer and withstand harsh conditions. There is also innovation in the making of fiberglass. Better manufacturing methods can make fiberglass reinforcement easier and less expensive to manufacture. And that could result in more builders incorporating it into their array of materials as an alternative to what they’ve got — which would be terrific for everybody.

In addition to our excellent products, we're also committed to continuing development and research to improve our products. Our customers are regularly consulted and we continue to invest in improvement to keep our products top of the line in their respective industries. Our technical support and after-sales assistance are second to none providing our customers with peace of peace of. Our profiles are sold to Southeast Asia and the Middle East, which total 60 fiberglass concrete reinforcement.

Our fiberglass concrete reinforcement to quality and innovation is what sets us apart from other companies in the market. We have over 40 years' experience in producing fiberglass rods, fiberglass profiles and tubes. Our commitment to customer satisfaction as well as continuous improvement makes us stand out from our competitors. Transparency and transparency are important to us. We want our clients to be informed and actively engaged.

One of the main selling features of our fiberglass products is their value Despite their excellent performance they are also cost-effective and provide great value for money Our wide range of sizes and customizable options allow our clients to find the ideal fiberglass concrete reinforcement to their requirements If it's a standard fiberglass profile or customized fiberglass rebar we have the ability to meet a variety of requirements In all we are able to make a variety of different fiberglass profiles including rods tubes and custom shapes

The fiberglass we use is recognized for their fiberglass concrete reinforcement durability, strength and adaptability. Our products are manufactured by using the latest techniques and quality materials. Our products, be it an aluminized rod to construct or a tubular of fiberglass to be used in industrial applications are designed to last. Our products are also lightweight and resist corrosion, making them perfect for many applications.

Copyright © Chongqing Dujiang Composites Co., Ltd. All Rights Reserved