Fiberglass utility poles: Benefits, uses, and top manufacturers

- Overview

- Recommended Products

Features:

Technical Parameters

Dimensions:

In terms of size specifications, composite poles and communication towers can be customized according to customer needs. Common specifications include diameter, wall thickness, length and other parameters to meet the needs of different scenarios and applications.

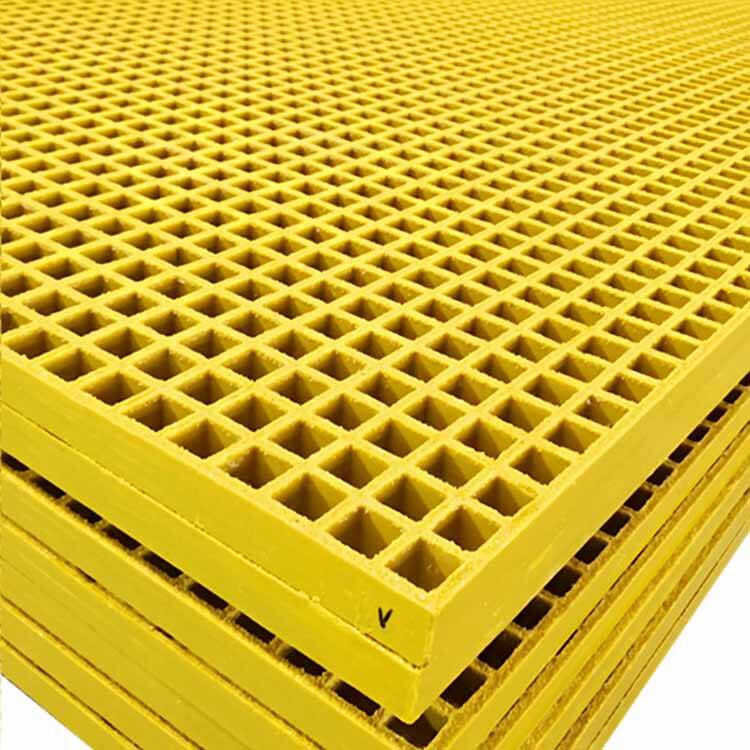

Material composition:

In terms of material composition, composite poles and communication towers are mainly composed of high- strength glass fiber and resin. These materials are processed by special processes and have excellent mechanical properties and corrosion resistance.

Application scenarios of composite poles

--Altitude ≤5000 m

--Thunderstorm days: 110 days/year

--Environmental relative humidity (at 25℃), daily average ≤95%, monthly average ≤90%;

--Earthquake resistance: Earthquake intensity VIII. Maximum design wind speed: 51m/s (10m above the ground, 10-minute average maximum value)

--Maximum annual rainfall: 2400mm Maximum daily rainfall: 375mm

--Maximum ambient temperature + 70℃; Minimum ambient temperature −40℃; Maximum daily temperature difference 60℃; Acid/alkali/salt corrosion environment: PH3-11

Rod material test items and performance requirements

| Serial number | Project Category | Test items | Performance requirements |

| 1 | Mechanical properties | Axial tensile strength | Tapered rod ≥300 MPa/Equal diameter rod ≥500 MPa |

| 2 | Axial bending strength | Tapered rod ≥300 MPa/Equal diameter rod ≥500 MPa | |

| 3 | Axial compressive strength | Tapered rod ≥300 MPa/Equal diameter rod ≥500 MPa | |

| 4 | Physical properties | Flammability | Not less than V-1 grade |

| 5 | Aging resistance | Acid resistance | Flexural modulus retention rate ≥80% |

| 6 | Alkali resistance | Flexural modulus retention rate ≥50% | |

| 7 | Salt resistance | Flexural modulus retention rate ≥85% | |

| 8 | UV aging | Flexural modulus retention rate ≥85% | |

| 9 | Alternating wet and hot aging | Flexural modulus retention rate ≥85% | |

| 10 | Constant temperature aging | Flexural modulus retention rate ≥85% | |

| 11 | Electrical performance | Surface resistivity | ≥1 . 0 × 10 ¹°Ω |

| 12 | Volume resistivity | ≥1 . 0 × 10 ¹°Ω · m |

Rod unit combination

| Unit pole number | Tip diameter/root diameter (mm) | Length(m ) | Remark |

| M1 | 190/350 | 12 | Single root |

| M2 | 190/390 | 15 | Single root |

| M3 | 230/390 | 12 | Single root |

| M4 | 270/430 | 12 | Single root |

| M5 | 310/470 | 12 | Single root |

| M6 | 350/510 | 12 | Single root |

| Illustrate | Pole length ≥12m, using two-section field connection (flange/socket) Pole length ≥24m, using three-section field connection (flange) Specifications not listed in the table can be customized according to user requirements | ||