How to Maintain and Extend the Lifespan of Your Fiberglass Tubes

Introduction

When selecting materials for industrial, construction, or manufacturing projects, engineers and project managers often face a critical choice: fiberglass tubes or steel tubes? Both materials have distinct advantages, but understanding their differences can help determine the best fit for specific applications.

This article compares fiberglass tubes and steel tubes in terms of strength, weight, corrosion resistance, cost, and durability, helping you make an informed decision for your next project.

1. Strength and Durability

Steel Tubes: High Tensile Strength

Steel is known for its exceptional tensile strength, making it ideal for heavy-load applications like construction beams, pipelines, and automotive frames. Steel tubes can withstand high pressure and impact, making them suitable for structural support in harsh environments.

However, steel is prone to fatigue over time, especially under constant stress or vibration. Additionally, rust and corrosion can weaken steel tubes if not properly treated or coated.

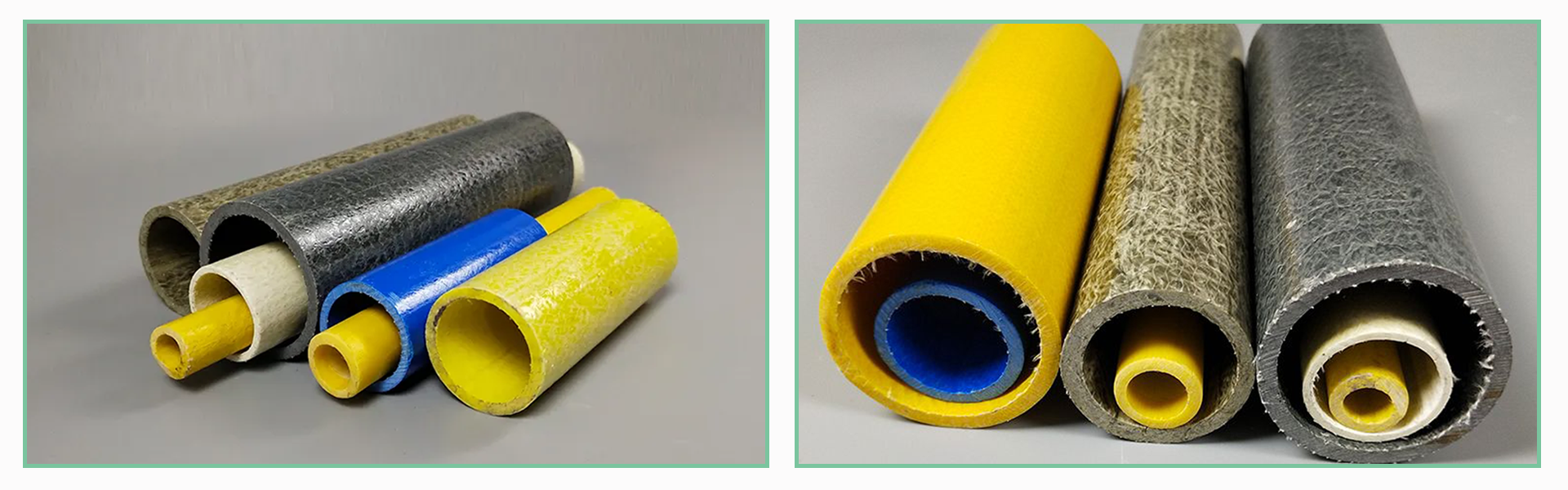

Fiberglass Tubes: High Strength-to-Weight Ratio

Fiberglass tubes, made from reinforced plastic (FRP), offer a high strength-to-weight ratio. While not as strong as steel in raw tensile strength, fiberglass is lighter yet highly durable, making it ideal for applications where weight reduction is crucial.

Fiberglass is also non-corrosive, meaning it won’t rust or degrade in wet or chemically aggressive environments. This makes it a preferred choice for marine, chemical processing, and outdoor applications.

Winner:

Steel for extreme load-bearing needs.

Fiberglass for lightweight, corrosion-resistant applications.

2. Weight Comparison

Steel Tubes: Heavy but Sturdy

Steel’s density makes it significantly heavier than fiberglass, which can increase transportation and installation costs. In applications like aerospace, automotive, or portable structures, excess weight can be a disadvantage.

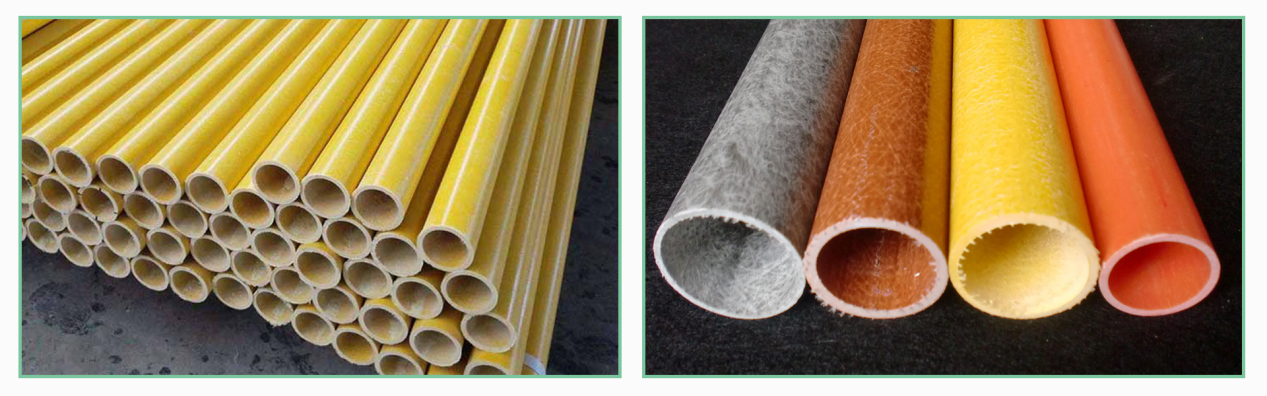

Fiberglass Tubes: Lightweight and Easy to Handle

Fiberglass tubes are up to 75% lighter than steel, reducing shipping costs and making installation easier. This makes them ideal for:

Aircraft components

Marine structures

Portable equipment

Winner: Fiberglass for weight-sensitive projects.

3. Corrosion and Chemical Resistance

Steel Tubes: Vulnerable to Rust

Even with protective coatings, steel is susceptible to rust, oxidation, and chemical degradation—especially in:

Marine environments

Chemical plants

High-humidity areas

Maintenance (e.g., repainting, galvanizing) adds long-term costs.

Fiberglass Tubes: Naturally Corrosion-Resistant

Fiberglass is immune to rust and chemical erosion, making it perfect for:

Offshore oil rigs

Wastewater treatment plants

Chemical storage tanks

Winner: Fiberglass for corrosive environments.

4. Thermal and Electrical Properties

Steel Tubes: Conducts Heat and Electricity

Steel is a thermal and electrical conductor, which can be a drawback in:

Electrical insulation applications

High-temperature environments (unless alloyed)

Fiberglass Tubes: Excellent Insulator

Fiberglass is non-conductive, making it ideal for:

Electrical enclosures

High-voltage applications

Thermal insulation systems

Winner: Fiberglass for insulation needs.

5. Cost and Long-Term Value

Steel Tubes: Lower Initial Cost, Higher Maintenance

Steel is generally cheaper upfront, but long-term costs include:

Anti-corrosion treatments

Frequent inspections

Replacement due to rust

Fiberglass Tubes: Higher Initial Cost, Lower Lifetime Expenses

While fiberglass tubes may cost more initially, they offer:

No maintenance against corrosion

Longer lifespan in harsh conditions

Reduced downtime for repairs

Winner: Fiberglass for long-term savings.

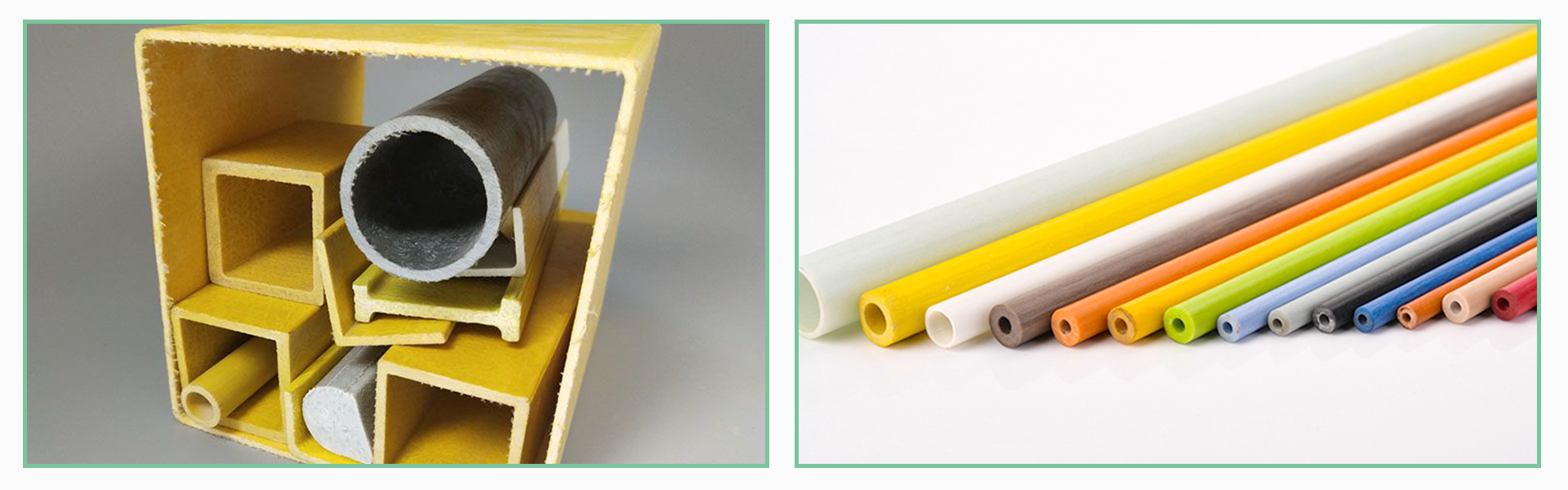

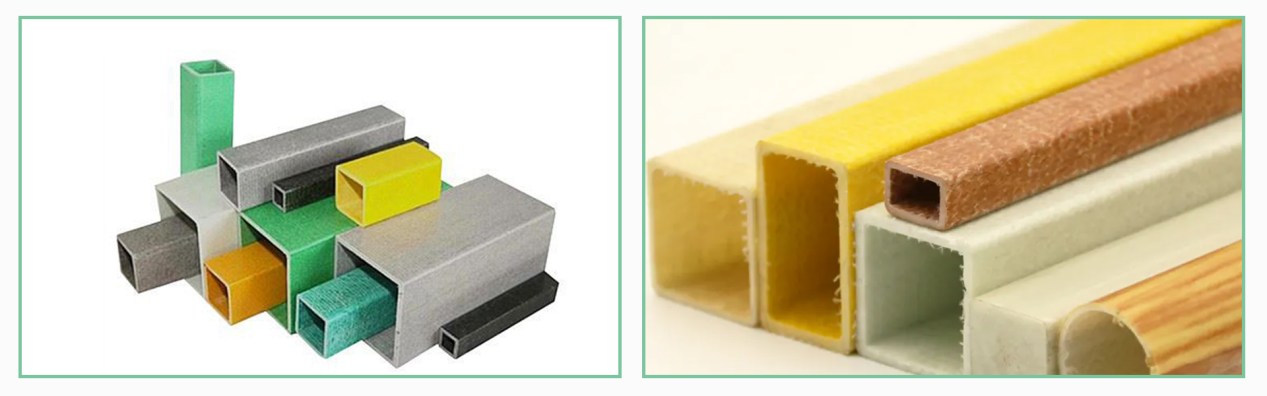

6. Applications: Where Each Material Excels

Best Uses for Steel Tubes

Building and bridge construction

High-pressure pipelines

Heavy machinery components

Best Uses for Fiberglass Tubes

Marine and offshore structures

Chemical processing equipment

Aerospace and automotive parts

Electrical and thermal insulation

Conclusion: Which Should You Choose?

The choice between fiberglass tubes and steel tubes depends on your project’s specific needs:

✅ Choose Steel If:

You need maximum strength for heavy loads.

Your project has minimal exposure to moisture/chemicals.

Initial cost is a bigger factor than long-term maintenance.

✅ Choose Fiberglass If:

You need lightweight, corrosion-resistant materials.

Your application involves chemical exposure or saltwater.

Long-term durability and low maintenance are priorities.

By understanding these key differences, you can select the best material for efficiency, cost savings, and performance.

Looking for High-Quality Fiberglass Tubes?

Chongqing Dujiang Composites Co., Ltd. offers custom fiberglass tubes for industrial, marine, and construction applications. Contact us today for a free quote!