How to Choose the Best Fiberglass Tubes for Your Needs

Introduction

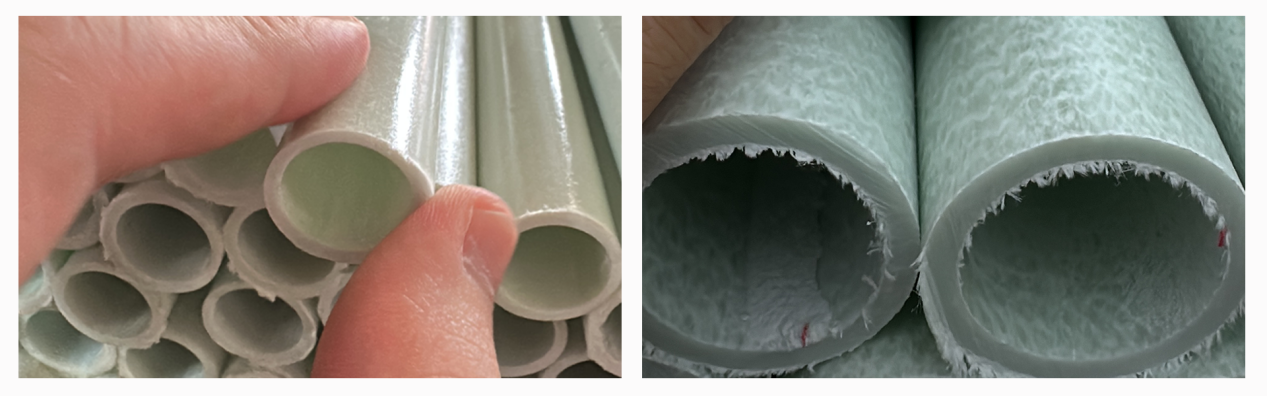

Fiberglass tube are widely used across industries due to their strength, lightweight nature, and corrosion resistance. However, selecting the right fiberglass tube can be challenging with so many options available. This guide will help you understand key factors like material composition, diameter, wall thickness, and application requirements to ensure you make the best choice for your project.

Understanding Fiberglass Tubes: Types and Composition

Fiberglass tube are made from reinforced plastic (FRP) with glass fibers for added strength. The two main types are:

E-Glass Fiberglass Tubes – Standard choice for general-purpose use, offering good electrical insulation and moderate strength.

S-Glass Fiberglass Tubes – Higher tensile strength and thermal resistance, ideal for aerospace and military applications.

Key Takeaway: If you need cost-effective durability, E-glass is sufficient. For extreme conditions, S-glass is better.

Key Factors to Consider When Choosing Fiberglass Tubes

A. Diameter and Wall Thickness

Larger diameters (e.g., 2" to 12") are used in construction and industrial piping.

Thinner walls reduce weight but may sacrifice rigidity.

B. Resin Type (Polyester, Vinyl Ester, Epoxy)

Polyester Resin – Affordable, good for general use.

Vinyl Ester Resin – Superior chemical resistance, ideal for corrosive environments.

Epoxy Resin – Highest strength, used in aerospace and high-performance applications.

C. Surface Finish (Smooth vs. Textured)

Smooth finishes are better for fluid flow.

Textured surfaces improve grip in structural applications.

D. Load-Bearing Capacity & Flexural Strength

Check manufacturer specs for:

Axial Load (compression resistance)

Flexural Strength (bending resistance)

Common Applications & How They Influence Your Choice

Electrical Insulation → Non-conductive, smooth-surface fiberglass tube.

Marine & Chemical Industries → Vinyl ester resin for corrosion resistance.

Automotive & Aerospace → High-strength S-glass with epoxy resin.

DIY & Hobby Projects → Lightweight, cost-effective E-glass tubes.

Where to Buy Quality Fiberglass Tubes (Trusted Suppliers)

Online Marketplaces: Amazon, eBay (for small quantities)

Industrial Suppliers: McMaster-Carr, Grainger

Specialized Manufacturers: Owens Corning, Fiberglass Warehouse

Pro Tip: Always check certifications (ISO, ASTM) and customer reviews before purchasing.

Frequently Asked Questions (FAQs)

Q: Are fiberglass tube stronger than steel?

A: While not as strong as steel by volume, fiberglass is stronger pound-for-pound and doesn’t corrode.

Q: Can fiberglass tubes be cut or drilled easily?

A: Yes, but use carbide-tipped tools to avoid splintering.

Q: What’s the average lifespan of fiberglass tubing?

A: 20+ years with proper maintenance, depending on environmental exposure.

Conclusion

Choosing the fiberglass tube tube depends on your specific needs—whether it's for industrial use, DIY projects, or high-performance applications. By considering factors like material type, resin composition, and load requirements, you can ensure optimal performance and longevity.

Ready to buy? Compare top-rated fiberglass tube now and make an informed decision!