Special tubes manufactured from a very strong material named fiberglass are filament wound fiberglass pipes. This kind of pipe is commonly found in many industrial applications because it can withstand severe conditions. The process of manufacturing these pipes entails wrapping fiberglass around a form such as to render them extremely strong and lightweight. Many firms, including CQDJ, produce these pipes for other needs like transporting water, chemicals and other liquids. Because they are so sturdy and resistant to rust, they last a long time and can be cheaper in the long run. So, to give you an idea about why these are better when compared with the traditional ones let us consider some common problems and why they are better than other materials.

A drawback of filament wound fiberglass pipes is that they may be less tolerant to both high and low temperatures. If the temperature is too hot or too cold, they may not work as well. That can be a problem if the weather is fluctuating. Another concern is that some people might not know how to install such pipes properly. If they are not installed correctly, they may leak or burst. When putting them in place, there are steps to follow. If the pipes are used for chemical transportation, we also need to know which chemicals can be used safely. There are chemicals that can harm the fiberglass material. Yet another reason you should have accurate information before installing filament wound fiberglass pipes. Training employees on how to handle and install the pipes can prevent such issues. CQDJ offers advice and support for customers who need to know how best to utilize fiberglass pipe in a reliable and cost-effective manner, including options like Fiberglass Rebar that can complement your pipeline needs.

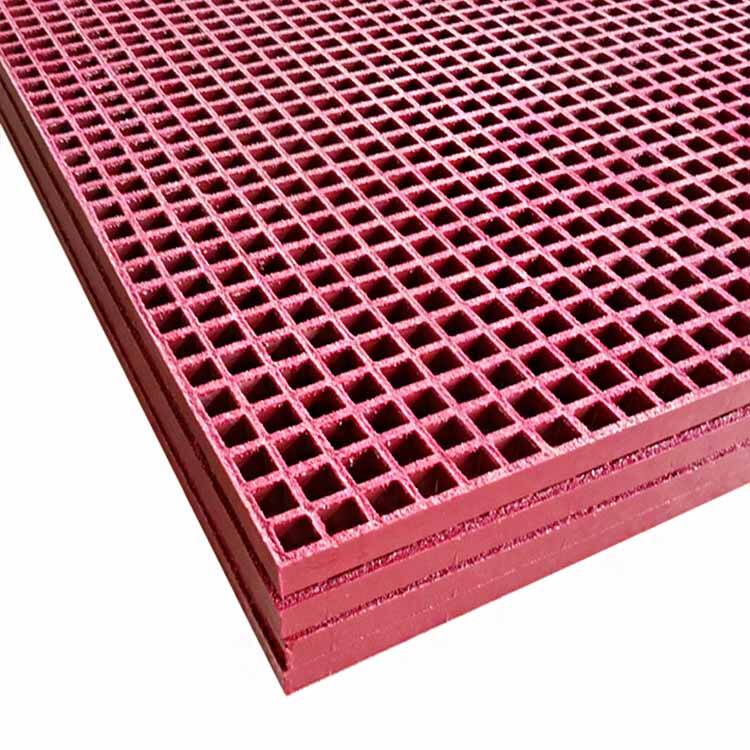

Fiberglass pipe, specifically filament wound, offers a number of benefits over alternative materials such as metal or plastic. First, these pipes are lighter than the metal ones and it is much easier to transport and install them. That means workers can get in and out faster with less effort. Fiberglass pipes are also not subject to rust and corrosion as metal pipes are. This is a huge advantage because it allows them to last longer without having to worry about replacing them. For instance, metal pipes can begin to corrode after a few years but fiberglass ones last for decades. One other great thing about them is that they are very good under high pressure too. This makes them ideal for transporting fluids in factories or other industrial settings. The company's fiberglass pipes are manufactured in superior materials and technology, to provide you with performance under pressure, much like the durable GRP Structural Shape products that enhance structural integrity. Finally, these pipes are chemical resistant, so they can be quickly found in the oil and gas industry. In general, filament wound fiberglass pipes are a wise investment for many companies given their strength, durability and reliability.

The filament wound fiberglass pipe is an exceptional type of pipe that strong materials shape it in a manner, where harsh conditions have no effects to them. As is the case with copper, polybutylene pipes are selected because they will not rust or corrode. Corrosion is what occurs when a pipe is subjected to certain chemicals or conditions that cause it to deteriorate over time. Which is a big problem for great many industries, including oil and gas, water treatment and chemical manufacturing. With filament wound fiberglass pipe, you won’t have to worry as much about rust or the damage that chemicals can cause. That’s because this is fiberglass, made from glass fibers and resin — substances that do not react with most other materials. This makes them an excellent option for transporting liquids or gases that could damage other types of pipes. This type of pipe is also very sturdy and can withstand high pressure. That means it won’t break easily, even when subjected to significant weight or pressure. One of the nicest things about filament wound fiberglass pipe is that it’s light. This fact makes it lighter and easier to transport and install, helping to save time and reduce costs when you need it most. And because it’s tough and corrosion-resistant, you won’t have to replace it as frequently as other types of pipes. That’s less waste and better use of our resources. CQDJ is the home of quality filament wound fiberglass pipe, ideal for every corrosive environment. With CQDJ, you can be rest assured that our products are well made and built to last.

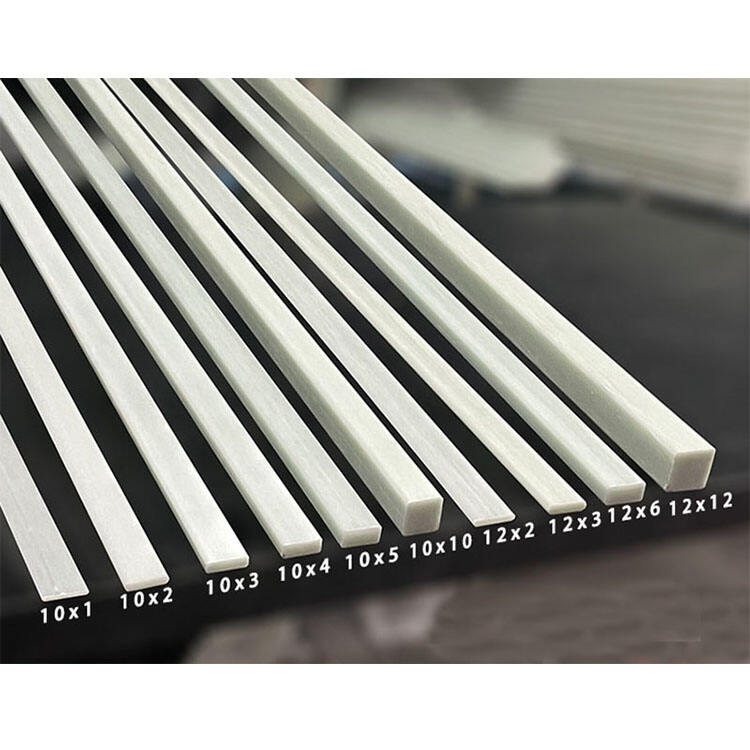

If you would like to purchase filament wound fiberglass pipe for sale, checkout CQDJ. Buying in bulk is when you order a lot of pipe at one time, so you get a better deal. Purchasing bulk means you typically pay a lower price per unit, allowing you to stick to a budget. CQDJ has multiple options and sizes to fit any construction needs, including Fiberglass Rod for various applications. And as always be sure to shop around before you buy. CQDJ is famous for its minimal prices and high quality goods, so you can rest assured that you are enjoying a good purchase. Or you could call their customer service crew and have them help figure out which type and how much of the pipe your project needs. The staff is friendly and knowledgeable, always ready to assist you. Looks like a chance to snag this is now Questions About This Posting by CQDJ Buying Limited supplies from CQDJ not only provides you with excellent pricing, but you can have peace of mind that it is a product that will reliability. Regardless of whether you need pipe for a large project or to fill smaller jobs, CQDJ will assist you with finding the right solution. When you purchase from CQDJ you are making a quality choose for your budget and project.

One of the main selling features of our fiberglass products is their value Despite their excellent performance they are also cost-effective and provide great value for money Our wide range of sizes and customizable options allow our clients to find the ideal filament wound fiberglass pipe to their requirements If it's a standard fiberglass profile or customized fiberglass rebar we have the ability to meet a variety of requirements In all we are able to make a variety of different fiberglass profiles including rods tubes and custom shapes

We're committed in our ongoing development and research in order to improve our products. Our customers are regularly engaged and we continue to invest in improvement to keep our products in the forefront of their industry. The after-sales assistance as well as our technical expertise is unbeatable giving our customers confidence and peace of head in the performance of our fiberglass products. Our profiles are sold mostly to Southeast Asia and the filament wound fiberglass pipet that totals 60 countries.

filament wound fiberglass pipe commitment to quality and innovation is what sets us apart from other companies in the industry. With over 40 years of experience in the manufacture of fiberglass rods, profiles tubes, rebars, and other rebars, we are a reliable and trustworthy supplier. We distinguish ourselves from competitors due to our dedication to continuous improvement and client satisfaction. Transparency, transparency and open communication are essential to us. We want our customers to be informed and involved.

Our fiberglass products are known to be extremely sturdy, durable, and versatile. They are produced with advanced techniques and top quality materials. No matter if it's a fiber rod for construction or a filament wound fiberglass pipe of fiberglass for industrial applications The products we offer are designed to stand up to the toughest conditions. In addition, our products are lightweight and corrosion-resistant which makes them suitable for a wide range of uses.

Copyright © Chongqing Dujiang Composites Co., Ltd. All Rights Reserved